Oct 11,2025

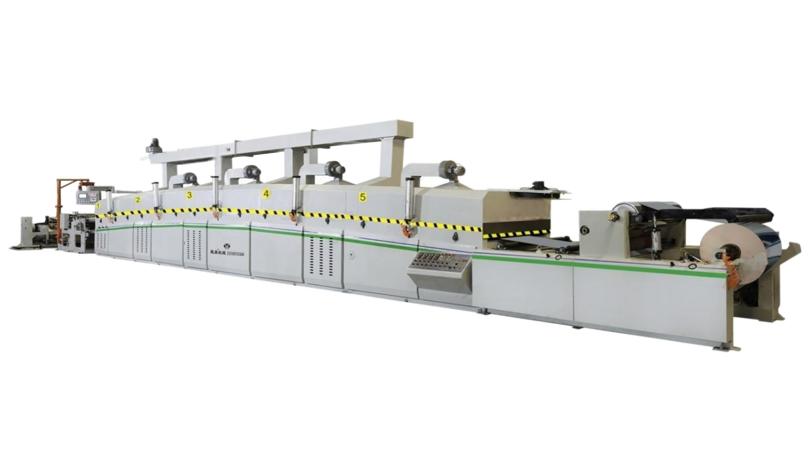

Oct 11,2025Definition: An automatic film laminating machine applies plastic film to paper or other substrates through heat and pressure

Process: Unwinds film rolls → preheats → applies adhesive → bonds to substrate → cools → winds finished product

How It Works: The Technical Breakdown

Key Components

1.Unwinding System: Precisely feeds both film and substrate materials

2.Lamination Unit:

* Heating elements (typically 50-150°C)

* Pressure rollers (adjustable 2-10 bar)

3.Cooling Section: Stabilizes the laminated product

4.Control Panel: Digital interface for parameter adjustment

Operating Principles

- Thermal Activation: Activates adhesive coatings

- Pressure Bonding: Creates permanent substrate-film union

- Speed Control: Modern Full Auto Film Laminators operate at 20-150 meters/minute

Advantages Over Manual Lamination

Productivity Gains

- * Output increased by 300-500% compared to manual processes

- * Continuous operation with minimal downtime

Quality Consistency

- 99.5% defect-free lamination

- Uniform thickness (±0.01mm tolerance)

Material Savings

- Precise film application reduces waste by 15-20%

- Optimal adhesive usage

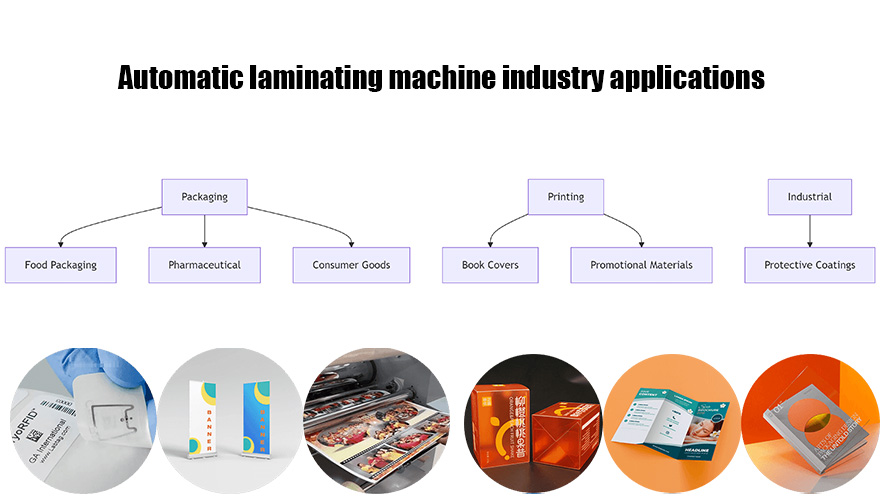

Industry Applications

Emerging Uses

- Flexible electronics manufacturing

- Solar panel encapsulation

- Smart packaging with integrated sensors

Selecting the Right Machine

| Factor | Consideration | Typical Range |

|---|---|---|

| Width Capacity | Determines max product width | 600-2500mm |

| Speed | Production throughput | 10-150m/min |

| Material Compatibility | Films/substrates processed | PET/PP/Paper/etc |

| Automation Level | Operator involvement | Semi-Full Auto |

Cost Considerations

- Entry-level: 15,000−15,000-15,000−50,000

- Industrial-grade: 80,000−80,000-80,000−300,000

- ROI period: Typically 12-24 months

Maintenance Requirements: Essential Practices

1. Daily:

- Roller cleaning

- Tension calibration

2. Weekly:

- Bearing lubrication

- Adhesive system inspection

3. Monthly:

- Heating element testing

- Full system diagnostics

Technology Trends

- AI Integration: Predictive maintenance systems

- Energy Efficiency: 30% reduction targets by 2025

- Advanced Materials: Biodegradable film compatibility

- IoT Connectivity: Remote monitoring capabilities

Market Outlook

- Projected CAGR: 6.8% (2023-2030)

- Asia-Pacific leading adoption

- Sustainable solutions driving innovation

This technology continues to transform manufacturing processes across multiple industries, offering unparalleled efficiency and quality in protective surface applications.

Tag: Laminating Machine, Film Laminator, Auto Rolling Laminator, Full Auto Film Laminator + Paper Separating Machine

.jpg)