Oct 11,2025

Oct 11,2025Laminating machines are essential tools in various industries, from printing and publishing to packaging and signage. They protect documents, labels, and other materials by applying a thin layer of plastic film. To ensure your laminating machine continues to operate smoothly and produce high-quality results, proper maintenance is crucial. Here are some essential maintenance tips for laminating machines.

General Maintenance Tips

1. Cooling Down

After using the laminator, always allow it to cool down before cleaning or storing. This not only prevents damage to the machine but also ensures your safety. High temperatures can cause burns and may also affect the integrity of the machine's components.

2. Cleaning

Regular cleaning is vital for maintaining the performance of your laminating machine. Use a soft, dry cloth to clean the machine's rollers and surfaces. Avoid using liquid cleaners, as they can seep into the machine and cause damage. For stubborn residue, you can use a mild cleaning solution specifically designed for laminating machines. However, always make sure to dry the machine thoroughly after cleaning.

3. Lubrication

If your laminator has moving parts, follow the manufacturer's guidelines for lubrication. Proper lubrication reduces friction and ensures smooth operation. Using the wrong type of lubricant can damage the machine, so it's important to use only the recommended products.

4. Storage

Store your automatic laminating machine in a clean, dry environment, away from direct sunlight and extreme temperatures. Exposure to sunlight and heat can cause the machine's components to deteriorate, while moisture can lead to rust and corrosion. If possible, store the machine in a protective cover to keep it clean and dust-free.

5. Maintenance Checks

Periodically inspect the machine for any signs of wear, loose parts, or other issues. Look for signs of damage on the rollers, such as nicks or scratches, as these can affect the quality of the lamination. Check for any loose wires or connections, and make sure all the buttons and controls are working properly. If you notice any problems, address them promptly to avoid further damage.

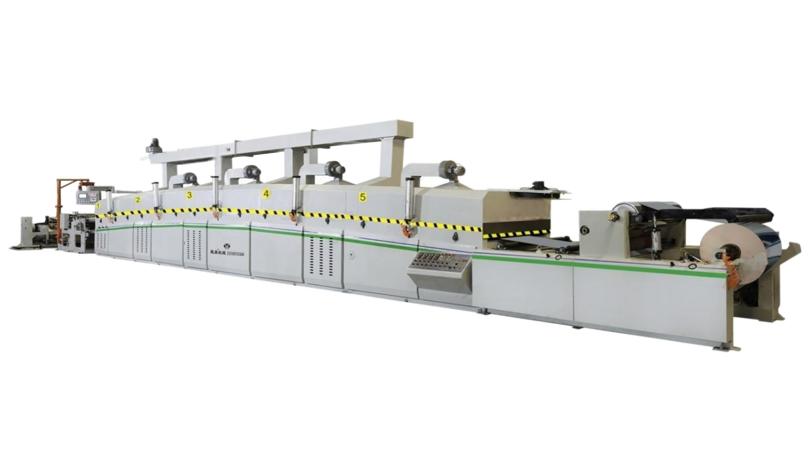

Automatic Laminating Machine Maintenance

Automatic laminating machines offer increased efficiency and productivity, but they also require specific maintenance to keep them running smoothly.

Speed and Efficiency

Regularly check the machine's speed settings to ensure it's operating at the optimal level. Over time, the machine may slow down due to wear and tear or improper settings. Adjust the speed as needed to maintain high productivity.

Adjustable Temperature Settings

Different materials and film types require specific heat settings. Make sure the machine's temperature control is accurate and adjust it according to the materials you're laminating. Incorrect temperature settings can result in poor adhesion or damage to the materials.

Film Thickness Compatibility

Ensure the machine can accommodate various film thicknesses. Check the manufacturer's specifications and adjust the machine's settings accordingly. Using the wrong film thickness can cause jams or other problems.

User-Friendly Controls

Keep the control panel clean and free of debris. Make sure all the buttons and indicators are working properly. If the controls are difficult to use or unresponsive, it can lead to errors and inefficiencies.

Safety Features

Regularly test the machine's safety features, such as auto shut-off, cool-touch exteriors, and safety shields. These features are designed to protect users from potential hazards, so it's important to ensure they're working correctly.

Choosing the Right Laminating Machine

When choosing a Full Auto Film Laminator, consider your specific needs and requirements. Here are some factors to keep in mind:

Intended Use

Determine what you'll be using the laminator for. If you're laminating large volumes of documents, you'll need a high-speed, industrial-grade machine. For small-scale projects, a desktop laminator may be sufficient.

Machine Size and Workspace Availability

Choose a machine that fits comfortably in your workspace. Consider the machine's dimensions, as well as the space required for loading and unloading materials.

After-Sales Support and Warranty

Opt for a machine with a comprehensive warranty and reliable after-sales support. This ensures that you can get help if you encounter any problems with the machine.

Conclusion

Proper maintenance of your laminating machine is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machine running smoothly and produce high-quality laminated materials. Whether you're using a manual or automatic laminating machine, taking the time to maintain it will pay off in the long run.

.jpg)