6000s/h Max speed

1080*800(mm) Max paper size

280*280(mm) Min paper size

Automatic Screen Printing Machine with smart operation: After completing the preparation work, simply press the run button to start the machine with full automation.

Smart open、Smart close

speed change with one key

Automatic positioning of pneumatic side-lay

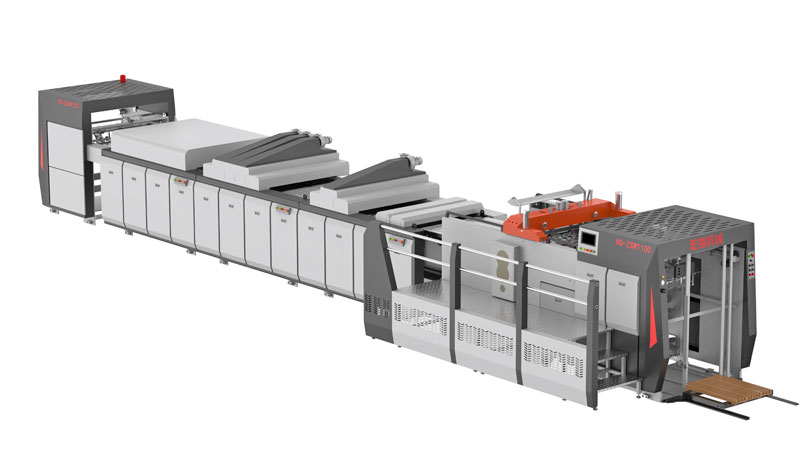

The ZDSY-1100A fully automatic screen printer is a new generation product developed by our company's R&D team, utilizing advanced domestic and international technologies. It offers screen printing solutions for complex designs, meeting our customers' screen printing needs.

This machine features high performance, high efficiency, and high precision. It can meet specialized surface finishing requirements for printed products, elevating the quality of your company's screen printing products to a new level. It saves manpower and material resources while significantly shortening production cycles.

This machine offers high flexibility, enabling rapid adjustment of printing parameters such as printing pressure, speed, and screen tension to meet the needs of different products. This flexibility enables it to meet a wide range of customized printing requirements, making it an ideal choice for producing high-end custom products.

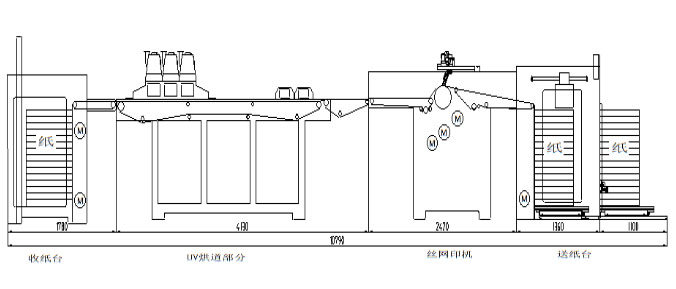

(1) This machine adopts a full servo intelligent control system, which can be started with one button and automatically completes the continuous actions of paper transportation, screen printing, drying, cooling, and paper collection. It is accurate, efficient, and easy to operate.

(2) This machine adopts a pneumatic pull gauge structure, which can accurately correct the deviation and effectively solve the marks caused by traditional mechanical pull gauges, ensuring the integrity of the printed product.

(3) The main machine of this machine adopts a double-layer cast iron wall panel to form the gear box. The lubricating oil in the box effectively increases the service life of the gear.

(4)This machine has an intelligent auxiliary calibration function, which makes the action more intelligent and the operation simpler. Through the control of HMI, each unit is automatically adjusted by the servo.

A. Intelligent Speed Control: Click the three-speed adjustment button on the screen to quickly reach your target speed. You can also click the plus or minus buttons to increase or decrease the speed within the specified range.

B. Intelligent Stop: Click the stop button on the screen to stop the machine after completing the current print job, eliminating material waste. Simultaneously pressing the emergency stop button immediately stops the machine, preventing unexpected situations and ensuring operational safety.

C. Automatic Left and Right Side Gauges: Enter the paper size on the screen, and the gauges automatically move to the specified position. Adjust the gauge position on the screen to fine-tune the color registration.

D. Controllable Color Offset: Set the color offset on the screen, and the machine automatically adjusts the timing between the print roller and screen frame, achieving fine-tuning of the color registration to meet customer requirements without manual adjustments.

E. Controllable Knife Drop Point: Set the starting point on the screen, and the machine will precisely control the drop and lift positions and timing of the print and ink return blades based on the corresponding values, supporting full-page printing. Pattern expansion and contraction compensation: Set the running speed compensation on the screen, and the equipment can automatically adjust the speed difference between the printing roller and the screen frame to correct the pattern expansion and contraction error, without the need for cumbersome mechanical top plate pulling, which is convenient and fast

(5) The paper collection unit automatically changes the plate without stopping the machine, which effectively saves the labor intensity of operators and improves work efficiency.

This machine uses Hongqiang's fourth-generation feeder, a servo-driven feeder that replaces the traditional drive shaft mechanism, effectively improving transmission stability and service life. The automatic paper feeder features pre-pushing and non-stop paper feeding, ensuring a consistent and stable transmission process, saving time and increasing production capacity.

A servo-type overlap mechanism ensures smooth, high-speed paper feeding. Under constant speed operation, the overlap accuracy is guaranteed to be ≤±1mm; under accelerated or decelerated operation, the overlap accuracy is guaranteed to be ≤±3mm. The automatic paper feeder has maximum and minimum paper sizes (based on technical specifications). In addition to paper width being limited by the format, the maximum and minimum paper lengths are also limited to a 3:1 ratio.

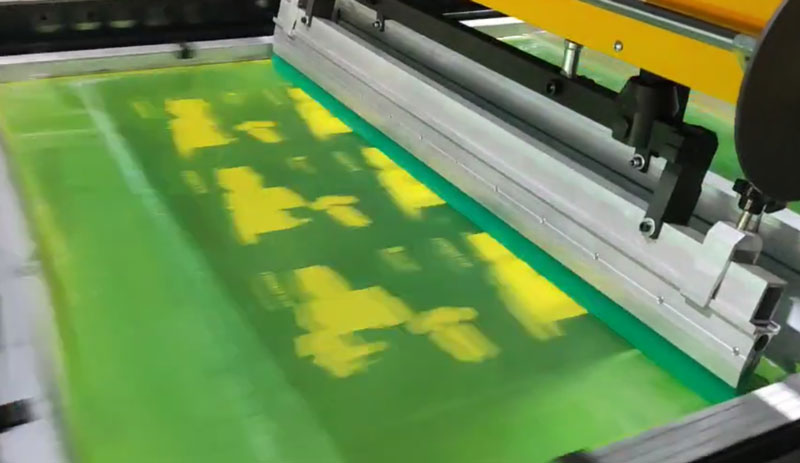

High-precision printing ensures that every subtle design element is perfectly rendered. It is particularly suitable for printing applications requiring highly accurate patterns and lines. Equipped with an automatic registration system and quick plate change, it significantly reduces makeready time and improves production efficiency. Its high-speed operation enables it to print large quantities of products in a short period of time, meeting the demands of large-scale production.

The mechanical components are designed to be highly robust and have a long service life, ensuring high-precision printing results over time. Furthermore, its stability and durability reduce maintenance frequency and production downtime.

The main screen printing unit utilizes a 28kW high-performance servo drive for the screen plate, enabling high-speed, high-precision reciprocating motion. The screen roller utilizes a 7.5kW high-performance servo drive. Together, these drives achieve a printing accuracy of 0.2mm and a printing speed of up to 4,500 sheets per hour.

The main control system utilizes a touchscreen display with one-button start-up and a simple, intuitive interface. Operation is simple and reliable, ensuring enhanced stability.

Utilizing advanced drying technology, the machine quickly dries and cures ink on printed materials, ensuring the printed image adheres firmly to the substrate. Equipped with an electronic temperature controller, the drying temperature is precisely controlled to ensure the ink dries and cures at the appropriate temperature, avoiding print quality issues caused by overheating or overcooling.

The machine also features a low-speed operation function that reduces UV power during operation, protecting the belt and machine, ensuring safety and longevity.

The automatic paper delivery features non-stop paper delivery, automatic table change, and double-sheet delivery, saving labor. It also features speed reduction for paper jam and continuous sheet detection, as well as automatic alarms.

|

Appendix: List of Major Purchased Parts |

|||

|

No. |

Name |

Brand |

Notes |

|

1 |

Encoder |

Omron |

Japan |

|

2 |

Contactor |

Schneider |

France |

|

3 |

High-Precision Servo |

Inovance |

China |

|

4 |

Circuit Breaker |

Schneider |

France |

|

5 |

Synchronous Belt |

Jaguar |

China |

|

6 |

Bearing |

NSK |

Japan |

|

7 |

Linear Guide |

Hiwin |

Taiwan |

|

8 |

Reducer |

Shengbang |

Taiwan |

|

9 |

High-Speed Feeder |

Hongqiang |

China |

|

10 |

Switching Power Supply |

Schneider |

France |

|

11 |

Pneumatic Components |

AirTAC |

China Taiwan |

|

12 |

Feeder Servo System |

Invt |

China |

|

13 |

Relay |

Schneider |

France |

|

14 |

Pressure Reducing Valve |

Jinqi |

China Taiwan |

|

15 |

Button |

Schneider |

France |

|

Model |

HQSY-1100A |

|

Max.paper sheet size |

1080mm*800mm |

|

Min. paper sheet size |

350mm*290mm |

|

Max. Printing size |

1080mm*780mm |

|

Screen frame size |

1140mm*1270mm |

|

Paper thickness |

128-500g/㎡ |

|

Printing speed |

100-4500 sheet/h |

|

Power |

3P 380V 50Hz 75kw |

|

Host machine Dimensions(L*W*H) |

5050*3500*2270 |

|

Overall Dimensions(L*W*H) |

10920*3500*2270(mm) |

|

Weight |

9800kg |

Oct 11,2025

Oct 11,2025

Oct 11,2025

Oct 11,2025

Sep 26,2025

Sep 26,2025 GET A QUOTE