Oct 11,2025

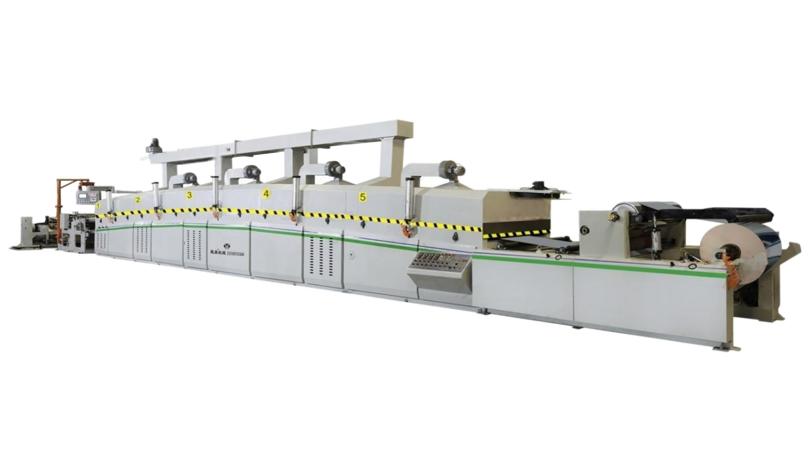

Oct 11,2025An automatic laminating machine is a high-efficiency industrial device designed to apply a thin plastic film layer onto various substrates, such as paper, cardboard, and printed materials, through heat, pressure, or adhesive bonding. This process, known as lamination, significantly enhances durability, improves visual appeal, and provides protection against moisture, dirt, and wear. Whether you're looking to safeguard important documents, elevate product packaging aesthetics, or boost the lifespan of printed materials, automatic laminators are the go-to solution for professionals across diverse industries.

Types of Automatic Laminating Machines

There are several types of automatic laminating machines available, each tailored to specific applications and requirements. Roll-to-roll laminators are ideal for high-volume production, continuously feeding materials through the lamination process. Sheet-fed laminators, on the other hand, handle individual sheets, making them suitable for smaller print runs and customized projects. Additionally, hot laminators use heat and pressure to activate adhesive coatings, while cold laminators rely on pre-coated adhesive films, eliminating the need for heat and preventing potential damage to heat-sensitive materials.

Key Benefits of Automatic Lamination

Investing in an automatic laminating machine offers numerous advantages over manual or semi-automatic alternatives. First and foremost, high-speed production capabilities ensure rapid processing of large quantities, reducing labor costs and increasing productivity. The consistent quality achieved by automated systems guarantees uniform lamination results, free from bubbles, wrinkles, or uneven adhesion. Moreover, automatic laminators provide enhanced versatility, accommodating a wide range of film thicknesses, substrates, and lamination finishes, including matte, glossy, and textured options.

Applications of Automatic Lamination

The versatility of automatic laminating machines makes them indispensable across various industries. In the printing and publishing sector, laminating protects books, magazines, brochures, and posters from damage, while enhancing their visual appeal. In packaging, laminated materials offer improved durability and shelf appeal, ensuring products stand out on store shelves. Signage and display applications benefit from lamination's scratch-resistant properties, maintaining the clarity and vibrancy of graphics over time. Additionally, automatic lamination is widely used in document preservation, photo protection, and ID card manufacturing.

Choosing the Right Automatic Laminating Machine

Selecting the appropriate Auto Lamination Machine depends on several factors, including production volume, substrate size, film type, and budget. Consider the lamination speed, width capacity, and film thickness compatibility to ensure the machine meets your specific requirements. Look for features such as user-friendly interfaces, adjustable temperature and pressure settings, and automatic tension control for optimal performance and ease of use. Additionally, choose a reputable manufacturer that offers reliable after-sales support and a comprehensive warranty.

Maximizing Lamination Results

To achieve the best results with your automatic laminating machine, follow these essential tips:

- 1. Prepare your materials: Ensure substrates are clean, dry, and free from dust or debris. Trim edges to prevent curling or misalignment during lamination.

- 2. Select the right film: Choose a film that matches the substrate type, application, and desired finish. Consider factors such as thickness, clarity, and adhesion properties.

- 3. Adjust machine settings: Calibrate temperature, pressure, and speed according to the film and substrate specifications. Conduct test runs to fine-tune settings for optimal results.

- 4. Maintain your machine: Regularly clean and lubricate the laminator to prevent build-up of adhesive residue and ensure smooth operation. Replace worn parts as needed to maintain performance.

Conclusion

An automatic laminating machine is a valuable investment for businesses seeking to enhance the quality, durability, and visual appeal of their printed materials and products. By understanding the different types, benefits, applications, and selection criteria, you can choose the right machine to meet your specific needs and achieve professional-grade lamination results. Whether you're a printer, publisher, packaging company, or signage provider, an automatic laminator is an essential tool for elevating your products and staying competitive in today's market.

.jpg)