Oct 11,2025

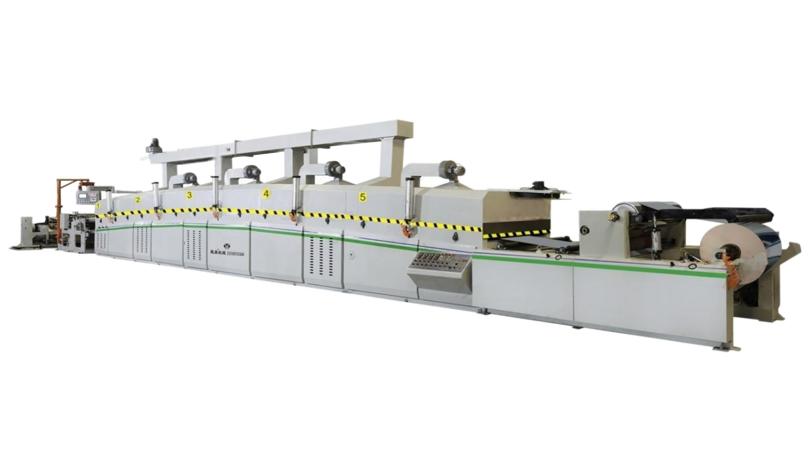

Oct 11,2025A Varnishing UV Machine, also known as an ultraviolet varnish coating machine, is a specialized piece of equipment that has been revolutionizing the print finishing industry. At its core, this machine utilizes a combination of coating mechanisms and ultraviolet light technology to apply a thin, protective layer of UV-curable varnish onto various printed materials, including paper, cardboard, plastic films, and labels.

How Does a Varnishing UV Machine Work?

The operation of a Varnishing UV Machine can be broken down into several distinct steps:

- Coating Application: First, the printed substrate is fed into the machine, passing through a coating unit. This unit may use different application methods, such as roller coating, spray coating, or screen coating, to ensure the UV varnish is evenly distributed across the surface. The UV varnish itself is a liquid formulation containing photoinitiators, monomers, and oligomers.

- UV Curing Process: Once the varnish is applied, the substrate immediately enters the UV curing chamber. Inside, high-intensity ultraviolet lamps emit UV radiation, triggering a chemical reaction in the varnish. The photoinitiators absorb the UV energy and initiate a polymerization process, rapidly transforming the liquid varnish into a hard, glossy, and durable solid film within seconds.

Advantages Over Traditional Varnishing Methods

- Speed: The instant curing enabled by UV technology significantly reduces production time, allowing for faster turnaround of print jobs.

- Enhanced Protection: UV varnish offers excellent resistance against scratches, abrasions, moisture, and fading, extending the lifespan of printed products.

- Visual Appeal: By adding a high-gloss or matte finish, it makes colors more vibrant and details more pronounced. For example, in the packaging industry, products with UV - varnished labels stand out on store shelves due to their enhanced luster and clarity.

Industries Where Varnishing UV Machines Are Used

- Graphic Arts and Printing: Employed to finish books, magazines, brochures, and promotional materials, giving them a professional look.

- Packaging Industry: Used to create eye-catching product packaging, from food and beverage containers to cosmetic boxes.

- Label Printing: Enables the addition of special effects, such as spot varnishing that highlights specific areas of a label, creating a tactile and visual contrast.

Related Topics

1. Environmental Considerations of UV Varnishing

Although UV varnishes are generally more environmentally friendly than solvent-based varnishes as they do not emit volatile organic compounds (VOCs) during the curing process, the production and disposal of UV varnish materials still have ecological impacts. The manufacturing of UV varnishes may involve non-renewable resources, and improper disposal of unused varnish or cleaning solvents can contaminate soil and water. As a result, the industry is exploring more sustainable UV varnish formulations, such as those made from bio-based materials, and improving waste management practices.

2. Integration with Digital Printing Technologies

The rise of digital printing has transformed the printing landscape, and automatic Varnishing UV Machines are evolving accordingly. Integrating UV varnishing technology with digital printing presses allows for on-demand, variable-data printing with high-quality finishing. This combination enables the production of personalized products with unique UV varnish effects, like custom greeting cards with spot varnishing on names or logos. However, challenges remain, including ensuring compatibility between different printing and varnishing systems, maintaining consistent quality across varying print volumes, and optimizing the workflow for maximum efficiency. Continued research and development aim to overcome these hurdles and unlock new possibilities for creative and customized print finishing.

.jpg)