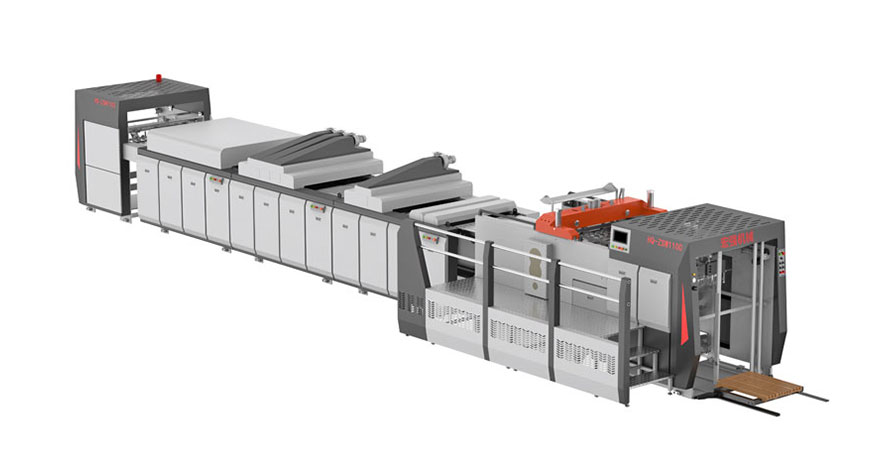

Adopting servo motor-driven fiducial paper feeding instead of the traditional drive shaft mechanism.

Adopting built-in segmented electromagnetic heating roller, it takes only 5 minutes to heat up 100℃, with high accuracy of constant temperature.

Adopt chain knife cutting function to cut PET film, laser film and other films, which can effectively solve the problems of laminating film burrs and rolled film.

Intelligent Start, Intelligent Speed Control, Intelligent Stop

Automatic positioning air pull gauge

Controllable printing knife drop point, controllable colour register offset.

Controllable colour register shift

Pattern expansion compensation

The main machine adopts cast iron wall plate, which can improve the stability and service life of the machine.

Three-roller reversing speed head, to ensure that the water-based varnish effect is not out of the stripe marks, metering rollers driven by a separate motor to ensure that the glue evenly.

Improved wind knife technology, suitable for thin paper (128-500 grams), to ensure that the paper over the oil is not attached to the roller, that is, anti-sticking roller.

-

High-speed & High-precision Placement

Vision system enables 12,000 placements per hour with micron-level accuracy. -

Wide Compatibility & Adaptability

Handles various card sizes and different substrates for diverse production needs. -

Stable Operation & Easy Maintenance

Robust structure with reliable core components ensures steady performance. -

User-friendly Intelligent Operation

Intuitive interface and flexible parameter settings for quick setup and use. -

Full Automation & Labor Saving

Automated from loading to finishing, significantly reducing manual intervention.

-

High Efficiency & Stable Performance

Ensures fast, automated, and stable operation for boosted productivity. -

Strong, Bubble-Free Lamination

High-temperature pressing guarantees firm adhesion and a smooth, flawless finish. -

Wide Material Compatibility

Handles various cardboard types and laminating films for diverse applications. -

User-Friendly Intelligent Control

Features an intuitive interface and simple parameter adjustment for easy operation. -

Robust & Durable Construction

Built with high-quality components for long-term, reliable performance.

For automatic die-cutting and semi-automatic die-cutting after all kinds of cardboard, trademarks (tags), plastic skin and other small packages, such as the automatic removal of the edges and pick-up special equipment.

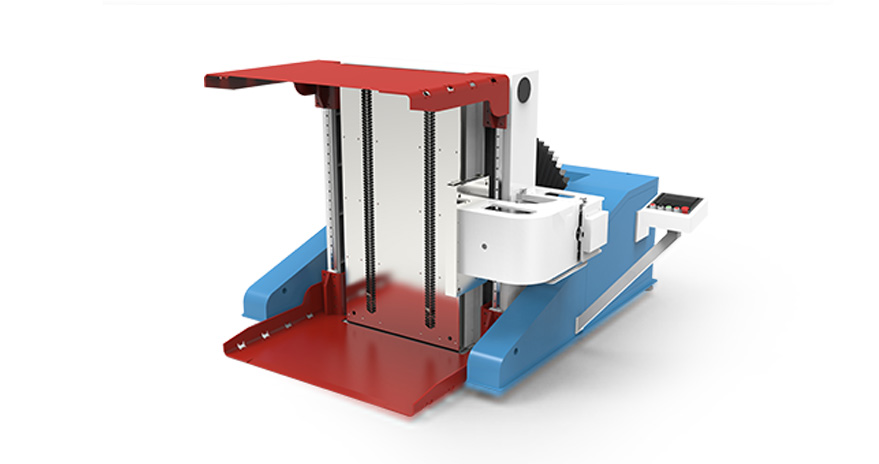

Adopting hydraulic structure, high-precision screw guide rail and servo programme control system to ensure machine durability and safe operation.

A new generation of paper finishing equipment, it can automatically complete the process of paper sorting, removing paper dust, blowing toner, etc.

It is the ideal equipment for handling large quantities of paper.

Handbag stringing machine solves the domestic and foreign market demand and has obtained dozens of national patents.

Practical and efficient, it is the ideal equipment for customers to solve the problem of stringing handbags and other packages.