40 pcs/min Production Speed

Φ5mm (Customizable) Rope hole Dia

110mm Hand rope length

20-100m/min Laminating Speed

1300*880(mm) Max. Paper Size

350*280(mm) Min. Paper Size

ZDFM-1100A automatic laminating machine is a new generation of products developed by the company using advanced technology at home and abroad, combined with the company's research and development team. For BOPP pre-coated film, BOPP non-adhesive film, and other film coating process, is the ideal equipment for multiple purposes.

The equipment has the characteristics of high performance and high efficiency. It can meet the professional needs of printed matter surface finishing, so that the quality of your company's laminating products to a new level. It not only saves manpower and material resources, but also greatly shortens the production cycle.

This machine adopts advanced technology at home and abroad. and is a new generation product developed by our R&D team. it is an ideal equipment for multi-purpose. for the coating process of PET precoat film. BOPp film. BOPP precoat film. BOPP non-adhesive film and laser film.

1. This machine adopts Feida paper feeding driven by servo motor instead oftraditional transmission shaft mechanism. which effectively improves the transmission stability and service life.

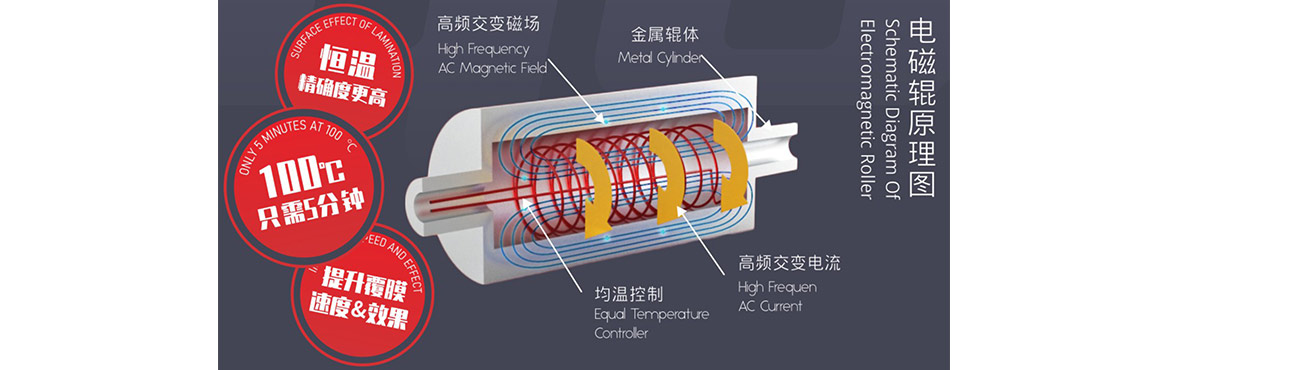

2. The machine adopts built-in segmented electromagnetic heating roller. which saves electricity, has fast heating speed (only 5 minutes at 100℃ ) and high constant temperature accuracy, and obviously improves the speed and surface effect of film coating.The segmented heating device can effectively protect rubber roller from aging.

3. This machine has the function of automatic change of the paper receiving table. which can save labor.

4.The machine adopts cast iron wallboard. which can improve the stability and service life of the machine.

5. The heat energy circulation system effectively reduces the heat energy loss. is more energy-saving and environment-friendly and improves the efficiency.

6. The machine adopts a rear view monitoring device. which can control the production status ofthe machine in multiple directions and save manpower and material resources.

7. One button start, double paper layout, low speed operation, speed memory and other functions make the operation more convenient.

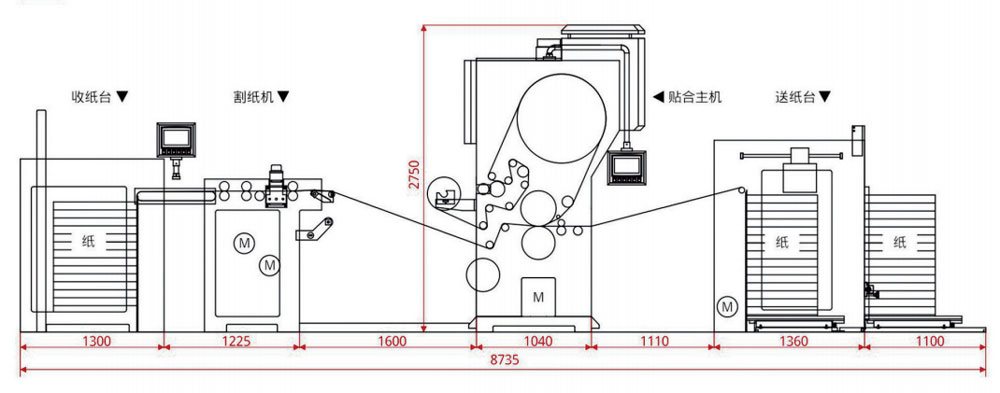

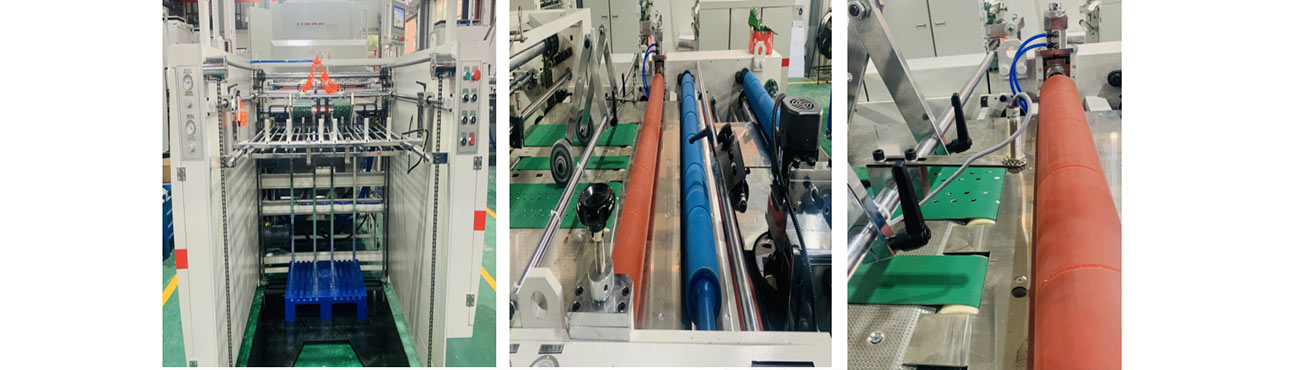

The equipment is mainly composed of paper conveying system, gluing drying system, laminating system, disk knife and paper breaking system, automatic paper receiving stacking system and PLC touch screen, high-precision servo motor electrical control system.

The printed matter is transported to the front gauge by the paper conveyor after positioning into , the feeding device is put into the film, gluing and drying, the paper and film through the pressing roller (electromagnetic heating) and the pressure rubber roller in the middle, pressurized and began to be coated. Use a disk knife or a friction sandpaper wheel to cut the overlap of the paper, and separate the paper through a paper drawing roller. Then the separated finished products are sent to the automatic paper receiving and stacking system in the conveyor belt for collection of single finished products. After neatly stacking, the film laminating process is completed.

|

Model |

Technical Parameters of the Equipment |

|

Max.paper sheet size |

1050mm*880mm |

|

Min. paper sheet size |

350mm*280mm |

|

Paper thickness |

80-650g/㎡ |

|

Laminating speed |

20-100m/min |

|

Applied Power |

52kw |

|

Production power |

22kw |

|

Reserve power |

30kw |

|

Air supply |

1000L/min 0.8Mpa |

|

Power supply |

380V 50Hz |

|

Weight |

8200kg |

|

Overall Dimensions(L*W*H) |

8735*2200*2750(mm) |

|

Overlap Precision |

≤+1mm |

|

Water base filmThickness(common) |

0.8/1.0/1.2/1.5 |

|

Common Glue Thickness |

4-10g/m² |

|

Pre-Gluing Film Thickness(common) |

15-35μm |

|

Non-Stop Feeding Height |

1200mm |

|

Collector Paper Height(incl. pallet) |

1050mm |

|

Contanaer |

40HQ |

|

HS code |

8439300000 |

1.The company does not provide air compressors;

2.Several factors that affect the speed of the machine: paper size/paper thickness and operator proficiency;

3.Due to continuous innovation in product design, the above data is for reference only; and are subject to change without notice.

•Paper splitting mechanism (commonly known as Feida head) : through the suction, blowing and transmission mechanism. Separate the pieces of paper from the pil

•High speed Feida, four suction and two feed stable and fast paper feed, the highest speed of up to 12,000 sheets/hour. The maximum speed can reach 12,000 sheets/hour

•The paper feeding table has upper and lower over-limit protection

•Feida servo drive is more efficient, sensor micromotion rise is more accurate, lifting plate can be fine-tuned more convenient

•The height of non-stop feeding can reach 1200mm, pre-stacking device, non-stop feeding

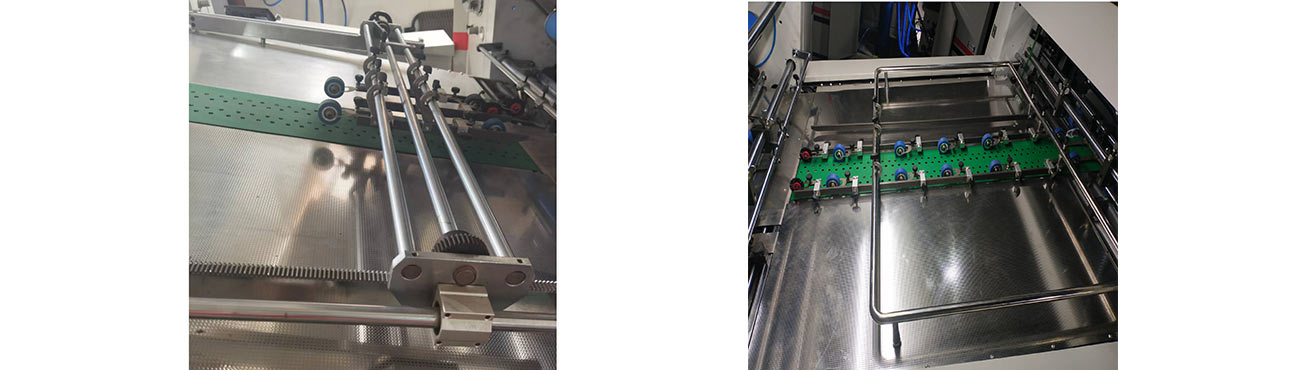

Conveying part

•The conveying table adopts stainless steel corrugated board.

•The press wheel is adjusted to the size of the paper to absorb air to prevent slipping,Automatic correction of pull gauge

•Servo control lap distance, lap error ≤±1mm

•The pre-pressing roller ensures the paper is flat

The film supply system smoothly releases the rolled film through tension control, the glue is evenly applied to the film through the upper roller, the drying system dries the glue on the film, the waste film cutting and receiving system cuts and rolls up the excess film, expands the film through the forward and backward bending roller, and smoothly sends it to the pressing roll. Through hydraulic motor, hydraulic pump, hydraulic oil, hydraulic tubing, hydraulic cylinder and automatic control hydraulic system, the pressing and separating of the pressure roll and the pressing roll are controlled.

• Drying stick diameter 803mm auxiliary film glue, quick dry. The film is heated evenly, the drying speed is faster, and the energy consumption is lower.

•The diameter of the rubber stick is 300. The auxiliary film is combined with the paper

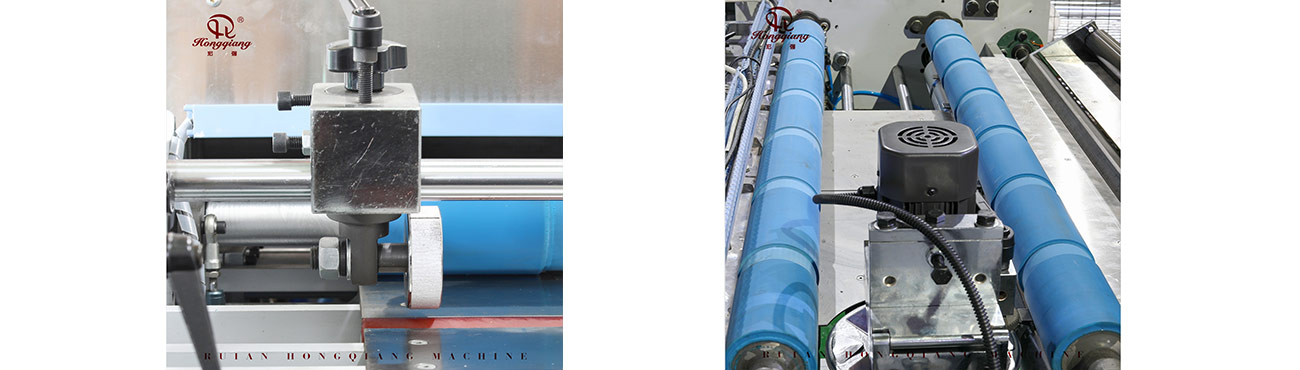

•Electromagnetic heating roller diameter 320, using electromagnetic heating system, heating and cooling fast, stable temperature, built-in temperature probe, accurate reading temperature. The heating roller adopts the segmented heating system, which is highly efficient and energy-saving

•The machine stops in an emergency, the film pressing frame automatically rises, the film is not polluted by glue. Gluing system Teflon process treatment, easy to clean non-stick

The hydraulic trolley is convenient for loading and unloading film,making it more convenient for workers to load and unload film,saving time and labor, and can also be used for maintenance and loading and unloading of pressure rollers

•The machine adopts built-in segmented electromagnetic heating roller, which saves electricity, has fast heating speed (only 5 minutes at 100℃)

•High constant temperature accuracy, and obviously improves the speed and surface effect of film coating. The segmented heating device can effectively protect rubber roller from aging.

•The built-in segmented electromagnetic heating roller is independently developed, designed and produced by our company's technical team, and has a patent for invention, which can realize the heating function

•It is China's technology is the most mature, and the heating method is unique

•The paper cutter is equipped with a tension controller, double sets anti roll structure, flat and non curly after thin paper laminating.

•The disc knife is used to break the paper and leave the opening in advance,The advantage is that the membrane can be more smoothly disconnected

•A transverse cut is more likely to cut through the membrane without damaging the paper,By a separate frequency control can be arbitrarily selected speed to cope with different situations

•The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference, assist to film break.

non-stop paper receiving height can reach 1200mm, when the paper pile is nearly full, the paper receiving conveyor belt automatically extends to accept the paper, the paper receiving platform drops, and rises to the set position after replacing the tray, the platform recovers, and the non-stop paper receiving is completed

•Adopt pneumatic paper sorting structure to ensure the neatness of the paper.With a reduction wheel to prevent the paper from being damaged due to too fast hitting the baffle.

•Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and kick out thepaper

Oct 11,2025

Oct 11,2025

Oct 11,2025

Oct 11,2025

Sep 26,2025

Sep 26,2025 GET A QUOTE