Oct 11,2025

Oct 11,2025In the fast-paced world of apparel and merchandise production, speed, consistency, and quality are non-negotiable. Manual printing methods, while valuable for artisans, simply cannot keep up with the demands of modern bulk orders. This is where the automatic screen printing machine becomes not just an upgrade, but a fundamental pillar for a competitive business. These sophisticated systems transform the printing process from a labor-intensive craft into a streamlined, high-output production line. For brands like HONGQIANG, which has built its reputation on engineering robust and intelligent printing solutions, the goal is to provide more than just equipment; it's about delivering a seamless bridge from design concept to flawless finished product. This article delves into the core advantages, diverse applications, and tailored support that define today's top-tier automatic printing technology.

The Unmatched Technical Superiority of Modern Automatic Screen Printing

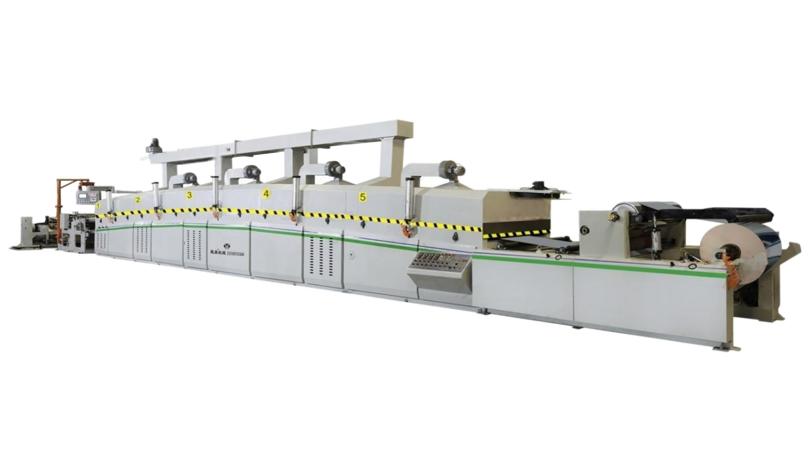

The evolution of the automatic screen printing machine is a story of precision engineering meeting user-friendly operation. Unlike their manual counterparts, these machines are designed for continuous, high-volume production with minimal human intervention. A standard HONGQIANG automatic screen printing press features a rotating carousel that holds multiple pallets. Each station is dedicated to a specific color or function—flashing, printing, or curing—allowing for simultaneous operations that drastically cut production time.

Key technological advancements include micro-processor controlled indexing for flawless registration, even at high speeds, and pneumatic systems that ensure consistent squeegee pressure and off-contact for every print stroke. This eliminates the variability of human operators, guaranteeing that the first shirt in a run is identical to the thousandth. The integration of high-speed automatic screen printing capabilities with precision is what sets industry leaders apart. Furthermore, modern machines often feature intuitive touchscreen interfaces, allowing operators to save and recall job settings for different designs instantly, reducing setup time and minimizing errors. This focus on automated textile printing equipment isn't just about doing things faster; it's about doing them smarter and with unwavering quality.

Driving Efficiency Across Diverse Production Scenarios

The true value of an automatic screen printing machine is realized in its application across various real-world scenarios. Imagine a large apparel decorator receiving an urgent order for 5,000 event t-shirts with a complex six-color design. With a manual setup, this order would be logistically daunting, requiring multiple presses and a small army of skilled printers, likely taking days to complete while battling fatigue and consistency issues.

Now, envision the same order on a HONGQIANG 10-station automatic press. The design is loaded, and the settings are recalled from memory. The machine automatically handles the precise application of each color, the flashing between layers, and the final cure. One or two operators simply load and unload garments, overseeing the process. The job is completed in a single shift, with every shirt meeting exact quality specifications. This scenario applies not only to cotton tees but also to automated printing for promotional products like hoodies, tote bags, and caps using specialized pallets. The flexibility of these systems allows businesses to accept a wider range of orders—from short-run, multi-color printing automation for boutique brands to massive bulk orders for corporate clients—making them an incredibly versatile asset.

HONGQIANG's Commitment to Customized Solutions and Partnership

Investing in an automatic screen printing machine is a significant decision, and the machine itself is only one part of the equation. The support, service, and customization behind it are what truly empower a business. HONGQIANG distinguishes itself by moving beyond a simple vendor relationship to become a strategic partner. Recognizing that no two print shops are identical, they offer profound customization options for screen printing machines.

This could mean configuring a press with a specific number of print stations to match a client's typical job requirements, integrating advanced flash cure units for high-density inks, or providing specialized firmware for unique substrates. Their comprehensive technical support for printing machinery includes extensive on-site installation and training, ensuring your team is confident and proficient from day one. This level of customized automatic screen printing solutions ensures that the technology adapts to your workflow and business goals, not the other way around. It’s a partnership focused on maximizing your uptime, your output, and ultimately, your profitability.

See the difference for yourself. Return to our Homepage to discover more about our full product portfolio and the stories of our successful clients.

.jpg)