1200-6000pcs/h Production speed

1080*720(mm) Maximum mounting dimensions

400*400(mm) Minimum mounting dimensions

120 m/min Maximum mechanical speed

≤Ф1500(mm) Maximum diameter of paper roll

4 roller transfer extension type Top Gluing Method

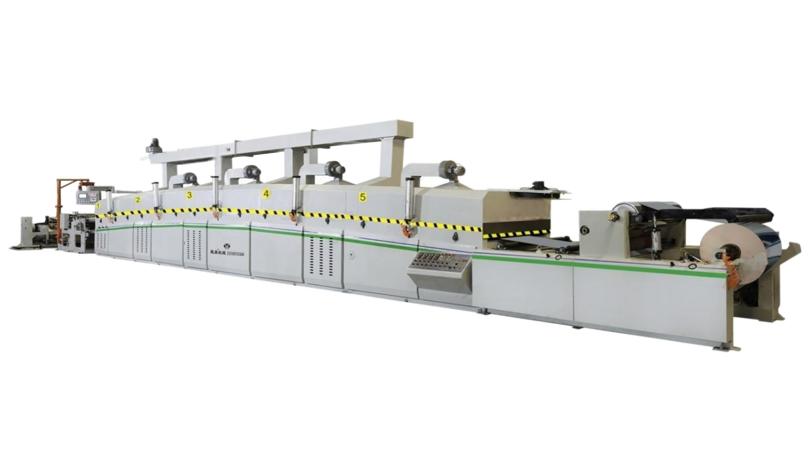

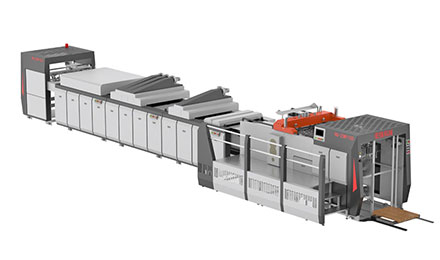

Application: This equipment is primarily used for processing roll materials such as gold card paper, silver card paper, laser-cut cardstock, and aluminum foil backing paper through a series of procedures including unwinding, gluing, lamination, coloring (coating and printing), drying, cooling, traction reduction, and rewinding. The final output is a composite packaging material with specific performance characteristics.

Key features: The system boasts an advanced control architecture with rational design, comprehensive configurations,high automation, and stable performance. Featuring intelligent Digital display controls for user-friendly operation, it delivers energy-efficient, eco-friendly solutions while ensuring precision in product alignment, optimal brightness, and superior Coating/printing quality. Outperforming domestic counterparts in industry standards, this equipment stands as the preferred choice for similar applications. It represents your smart investment in precision manufacturing solutions.

Gold and silver card products are widely used in the prepress deep processing technology of printing for high-grade inner and outer packaging boxes such as cigarette cases, wine cases, medicine cases, cosmetic cases, food boxes (cake boxes, mooncake boxes, local products boxes), gift boxes, toy boxes, toothpaste boxes, etc.

Gold and silver cardboard production equipment designed and manufactured to suit modern domestic gold and silver cardboard, laser materials, tobacco and wine packaging materials. The multifunctional machine with the functions of unwinding, gluing, coloring, hot air drying and winding is centralized controlled by imported PLC and controlled by touch screen. At present, the most perfect technology, the most complete function and the most advanced control technology in China are the ideal gold card paper composite equipment.

Wet and dry gold and silver card composite process:

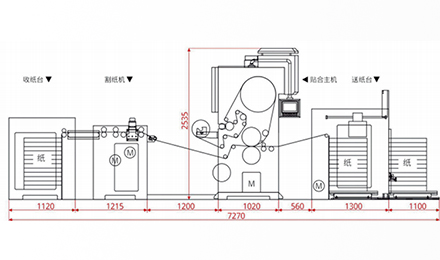

Roll paper (spool 1) + roll aluminum foil/membrane (spool 2) → apply adhesive to four rolls → composite → color application 1 (plate coating) → drying (hot air drying in oven) (12.5 meters, 5-section oven "Standard configuration") → air cooling → s-shaped 3-roll cooling and traction → central winding → hydraulic unloading.

| Name | Key Technical Parameters |

| Thickness of paper | 40 ~ 450 grams per square meter of roll paper |

| Thickness of film or aluminum foil | 0.0063 ~ 0.01 mm aluminum foil, 0.012 ~ 0.06 mm film |

| Width of composite product | 600~1200 mm |

| Rolling width | 1300 mm |

| Maximum diameter of paper roll | ≤Ф1500 mm |

| Release paper core specifications | 3, 6, 12 inch coil cores |

| Specification of collecting paper core | 6 inch cartridge |

| Roll diameter of film or aluminum foil | ≤Ф500 mm |

| Specification of membrane or aluminum foil core | 3 inch core (inner diameter Ф76 mm outer diameter Ф96 mm) |

| Maximum mechanical speed | 120 m/min (50-120 m/min according to process and material) |

| Top Gluing Method | 4 roller transfer extension type |

| Coloring Method 1 (also known as upper clear oil printing) | Lining structure (mesh roller on top, rubber roller on bottom) |

| Drying Method | Electric heating, hot air circulation |

| Oven length | 5 sections * 2.5 meters =12.5 meters, 5 section control bridge structure Energy saving and environmental protection Oven |

| Cooling-down Method | Wind Cooling + S Type Double-sided Forced Cooling (the customer has to provide the Chiller) |

| Tension Montrol | PLC automatic closed loop automatic control |

| Master Mode | 10-inch touch screen control, siemens plc programmable centralized control |

| Total machine power | 120 kW , 380 V ,50 Hz (standard model) |

| Dimensions (maximum) | 22 meters long, 3 meters wide and 3.2 meters high |

| Operational Position | When you stand behind the paper rack, the left side is the operation surface |

Sep 10,2025

Sep 10,2025

Jul 07,2025

Jul 07,2025

Jun 24,2025

Jun 24,2025 GET A QUOTE