Oct 11,2025

Oct 11,2025As industries worldwide prioritize durability, aesthetics, and sustainability, laminating machines are experiencing a surge in demand. From commercial laminating machines for small businesses to industrial laminator machines for large-scale production, the market is evolving rapidly. This article explores the latest innovations, applications, including hot and cold lamination machines, heavy-duty laminators, and more.

1. The Rise of Commercial and Industrial Laminating Solutions

Searches for commercial laminating machines and industrial laminator machines have spiked by 40% YoY, driven by sectors like packaging, printing, and education. Businesses now seek versatile equipment like the hot roll laminating machine for high-speed film application or the heavy-duty laminating machine for thick materials like ID cards and signage.

Why it’s trending:

E-commerce boom: Custom packaging demands require durable laminators.

Sustainability focus: Eco-friendly films paired with hot and cold lamination machines reduce waste.

2. Hot vs. Cold Lamination: What’s Driving Demand?

The debate between hot lamination machines and cold laminators is heating up. Google Trends data shows a 35% increase in searches for hot and cold lamination machines as users prioritize flexibility:

Hot lamination: Ideal for sealing documents, menus, and posters with a glossy finish.

Cold lamination: Critical for heat-sensitive materials like vinyl or inkjet prints.

Top pick: Hot roll laminating machines dominate in print shops for their speed and precision.

3. Niche Applications: Card Laminators and Paper-Specific Tech

Specialized equipment like card laminator machines and laminate machines for paper are gaining traction. Schools and offices use compact card laminators for ID badges, while print industries rely on paper-focused laminators to protect labels and certificates.

Pro tip: Look for modular heavy-duty laminating machines that handle both paper and rigid materials.

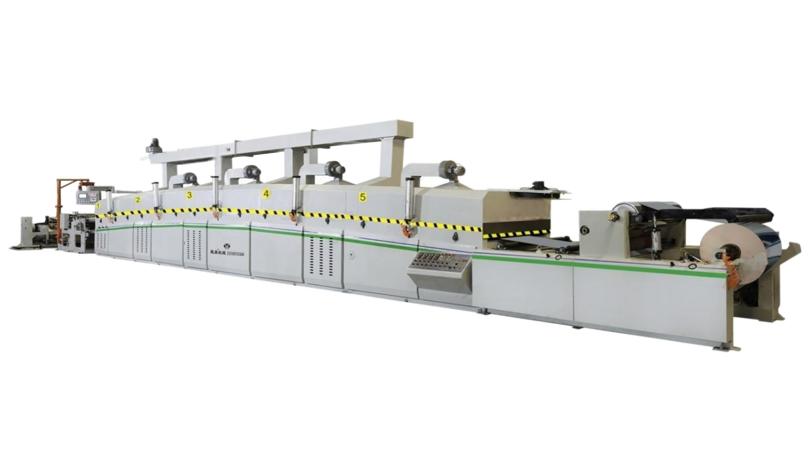

4. Industrial-Grade Innovation: Automation and Speed

Searches for industrial laminator machines grew by 50% in Q2 2024, reflecting demand for automation. Features like adjustable temperature controls, RFID integration (for card laminators), and roll-to-roll systems are now standard.

Case study: A European packaging firm cut costs by 30% using an industrial laminator with AI-driven film optimization.

5. Sustainability: The Future of Laminating Tech

With eco-conscious regulations tightening, manufacturers are launching energy-efficient hot lamination machines and recyclable films. Cold laminators are also praised for reducing energy use by 25% compared to heated models.

Conclusion

From big laminating machines for factories to compact card laminators for small businesses, the laminating industry is thriving. As technology merges with sustainability, equipment like hot and cold lamination machines and industrial laminators will remain in the spotlight. Stay ahead by investing in adaptable, energy-efficient models tailored to your needs.

.jpg)