Oct 11,2025

Oct 11,2025In modern manufacturing and material processing, the demand for flawless, durable, and multi-layered products has driven innovations in bonding technologies. At the forefront of this revolution are Automatic Laminating Machines (ALMs) and Auto Lamination Machines, engineered to deliver unmatched efficiency, consistency, and versatility. This article explores the science, applications, and advancements behind these transformative systems, shedding light on their role in industries ranging from packaging to electronics.

What is an Automatic Laminating Machine?

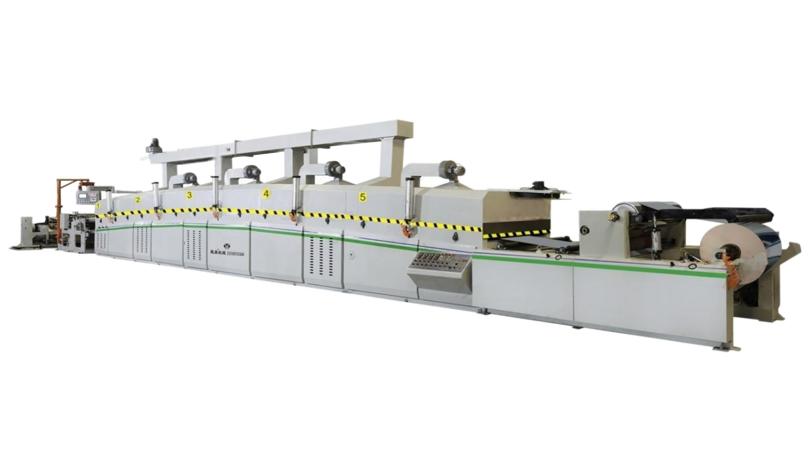

An Automatic Laminating Machine is a high-precision device designed to bond multiple layers of materials—such as films, foils, fabrics, or polymers—using controlled heat, pressure, or adhesive activation. Unlike manual or semi-automated systems, ALMs integrate advanced robotics, digital control systems, and real-time feedback mechanisms to optimize the lamination process. Key components include:

-

Feed and alignment systems: Ensure precise material positioning.

-

Thermal or cold lamination modules: Activate adhesives without damaging heat-sensitive substrates.

-

Pressure rollers: Apply uniform force for bubble-free bonding.

-

Quality inspection sensors: Detect defects like delamination or misalignment.

The term Auto Lamination Machine often refers to compact or specialized variants tailored for niche applications, such as laminating ID cards, flexible circuits, or photovoltaic panels.

Core Technologies Driving Automation

1. Adaptive Adhesive Activation

Modern ALMs support diverse adhesive types, including:

Pressure-sensitive adhesives (PSAs): Ideal for low-temperature applications.

Thermoplastic adhesives: Activated via precise heat control.

UV-curable resins: Used for rapid curing in electronics manufacturing.

2. Smart Process Control

PLC (Programmable Logic Controller) systems and IoT-enabled interfaces allow operators to adjust parameters like temperature, speed, and pressure in real time. Machine learning algorithms further enhance yield rates by predicting and correcting process deviations.

3. Multi-Layer Compatibility

ALMs handle complex material stacks, such as metal-polymer composites for automotive shielding or barrier films for food packaging. Advanced models even enable sequential lamination for products requiring 5+ layers.

Industry Applications: Where Precision Meets Innovation

1. Flexible Electronics

Auto Lamination Machines are critical in producing foldable displays, printed circuit boards (PCBs), and thin-film batteries. They ensure micron-level alignment of conductive layers while preventing electrostatic discharge (ESD).

2. Sustainable Packaging

ALMs bond recyclable films to paper or bioplastics, creating eco-friendly pouches and labels. Some systems incorporate laser scoring to facilitate easy recycling.

3. Automotive and Aerospace

From interior trim laminates to lightweight carbon-fiber composites, ALMs enhance durability and aesthetics while meeting strict flammability and VOC standards.

4. Medical Device Manufacturing

Sterile packaging, breathable wound dressings, and biocompatible sensor arrays rely on contamination-free lamination processes.

Advantages Over Traditional Methods

Speed: ALMs achieve throughputs of 30–100 meters/minute, versus 5–15 m/min for manual systems.

Waste Reduction: AI-driven defect detection cuts material scrap by up to 20%.

Labor Savings: Fully automated workflows reduce dependency on skilled operators.

Repeatability: Sub-millimeter precision ensures batch-to-batch consistency.

The Future of Auto Lamination Technology

Emerging trends include:

Hybrid Lamination-Die Cutting Systems: Combine bonding and shaping in a single pass.

Energy-Efficient Designs: Use infrared heating or regenerative braking to lower power consumption.

Nano-Adhesives: Enable ultra-thin, high-strength bonds for wearable tech.

Conclusion

Automatic Laminating Machines and Auto Lamination Machines represent the pinnacle of industrial automation, transforming raw materials into high-performance products with surgical precision. As industries push the boundaries of material science, these systems will remain indispensable for achieving sustainability, scalability, and innovation. Whether laminating a smartphone screen or a solar panel, ALMs prove that the future of manufacturing is not just automated—it’s intelligently layered.

.jpg)