Oct 11,2025

Oct 11,2025Laminating paper is a practical way to protect documents, posters, or promotional materials from wear, moisture, and fading. Whether you’re working in a school, print shop, or industrial setting, using the right laminating machine ensures professional results. Below, we break down the process step-by-step and highlight key machines tailored to different needs, including Commercial Laminating Machines, Industrial Laminator Machines, and specialized options like Hot and Cold Lamination Machines.

Step 1: Choose the Right Laminating Machine

Selecting a machine depends on your volume, material size, and application:

For small-scale projects: Opt for Swingline Laminating Machines or Laminate Machines for Paper, ideal for offices or classrooms.

For large-format materials: Use Wide Format Laminating Machines or Poster Laminating Machines to handle oversized prints.

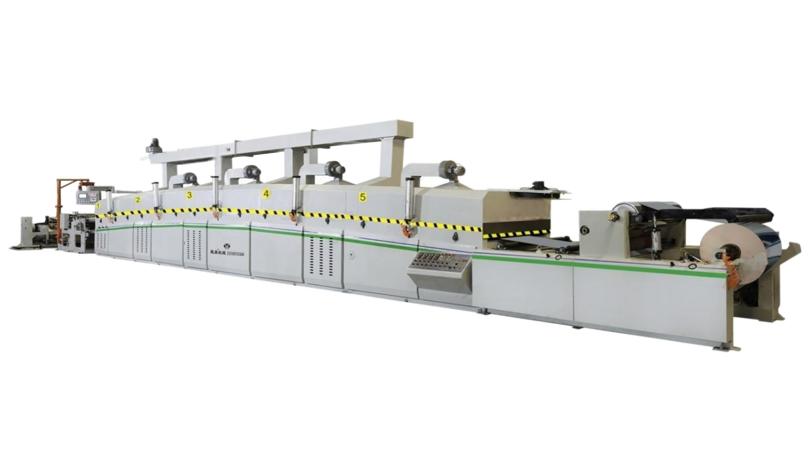

High-volume industrial needs: Heavy Duty Laminating Machines, Automatic Laminators, or 5 Ply Flute Laminators deliver efficiency for continuous use.

Versatility: Hot and Cold Lamination Machines support both heat-activated and pressure-sensitive films.

Step 2: Prepare the Materials

Ensure your paper is clean and dry.

Select appropriate Laminating Machine Sheets or rolls based on thickness (e.g., 3mil, 5mil).

For automated workflows, Auto Feed Laminators or Fully Automatic Paper Lamination Machines streamline material loading.

Step 3: Set Up the Machine

1. Temperature and Speed:

* Hot Roll Laminating Machines and Thermal Lamination Machines require precise heat settings (typically 250–300°F).

* Cold Lamination Machines eliminate heat, ideal for heat-sensitive materials.

2. Adjust Pressure: Industrial-grade machines like Automatic Flute Laminators or Sheet to Sheet Lamination Machines often include pressure controls for thick materials.

3. Load Film: For Roll Laminator Machines, align the film roll with the machine’s feed mechanism.

Step 4: Run the Lamination Process

1. Feed the paper into the machine manually or use Auto Feeder Lamination Machines for hands-free operation.

2. Monitor the process to avoid wrinkles or bubbles. Machines with Laminators Lamination Auto Cutters trim edges automatically.

3. For complex tasks, Semi-Automatic Flute Laminators balance control and efficiency.

Step 5: Finalize and Inspect

Allow laminated materials to cool (for hot processes).

Check for imperfections. Commercial Laminating Machines and Industrial Laminator Machines often include quality assurance features.

Top Machine Recommendations

-

Schools/Offices: Laminating Machines for Schools, Uline Laminating Machines, or Card Laminator Machines for ID badges.

-

Print Shops: Large Format Laminating Machines or Poster Laminators.

-

Industrial Use: Automatic Thermal Lamination Machines, Big Laminating Machines, or Fully Automatic Paper Lamination Machines.

-

Specialized Needs: Laminate Machine for Paper with auto-cut features or Hot Lamination Machines for glossy finishes.

Maintenance Tips

* Clean rollers regularly to avoid adhesive buildup.

* Store Laminating Machine Sheets in a dry, dust-free environment.

* Schedule servicing for Heavy Duty Laminating Machines to maintain peak performance.

By understanding your needs and leveraging the right equipment—from Auto Lamination Machines to Industrial Laminators—you can achieve flawless, durable lamination results every time. Invest in quality machines like Swingline Laminators or Automatic Flute Laminating Machines to boost productivity and protect your materials for years to come.

.jpg)