1200-6000pcs/h Production speed

1080*720(mm) Maximum mounting dimensions

400*400(mm) Minimum mounting dimensions

|

MODEL PRICE |

HY-450TB-S |

|

DELIVERY TIME |

45-60 work days |

|

PAYMENT ITEMS |

30%TT in advance, 70% TT before loading the container |

|

HS CODE |

8441200000 |

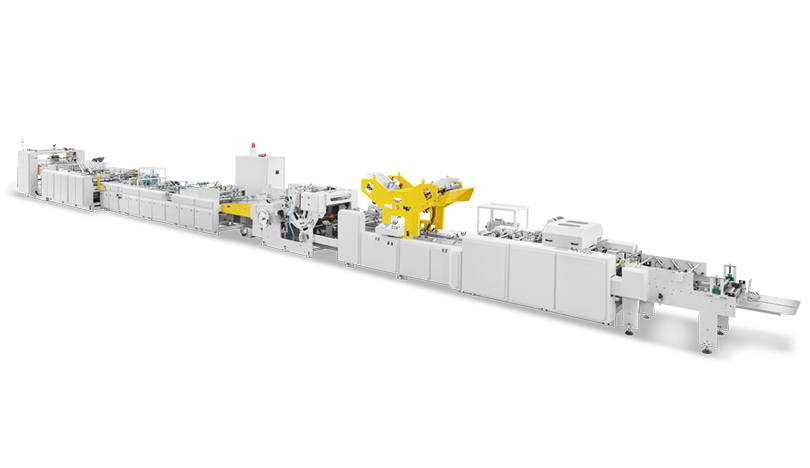

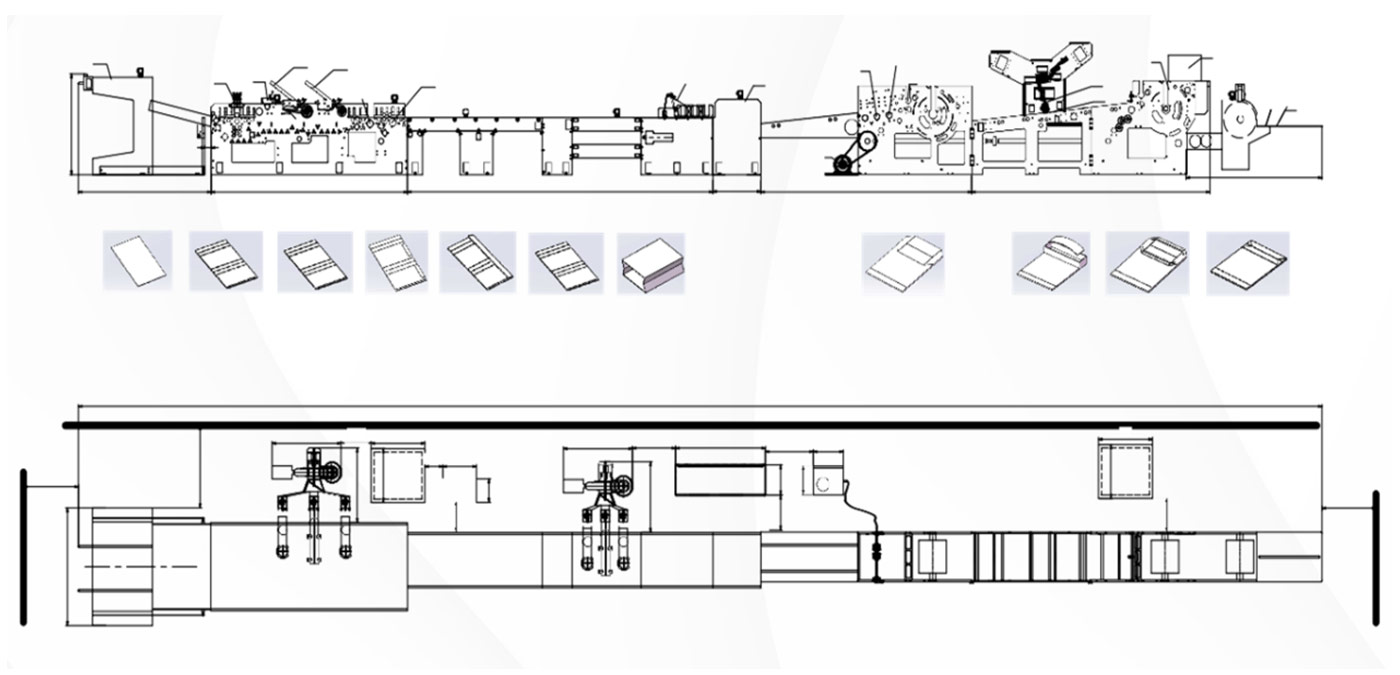

This machine is the world's first linear structure design automatic paper bag machine for top and bottom card pasting, integrating functions such as non-stop high-speed paper feeding, automatic creasing, sheet-type top card pasting (up to four sheets), automatic top folding, bag mouth interlaced tube forming, automatic accordion folding, bottom pulling, bottom opening, double-station bottom card conveying, automatic gluing and bottom card pasting, bottom sealing, and compaction forming.

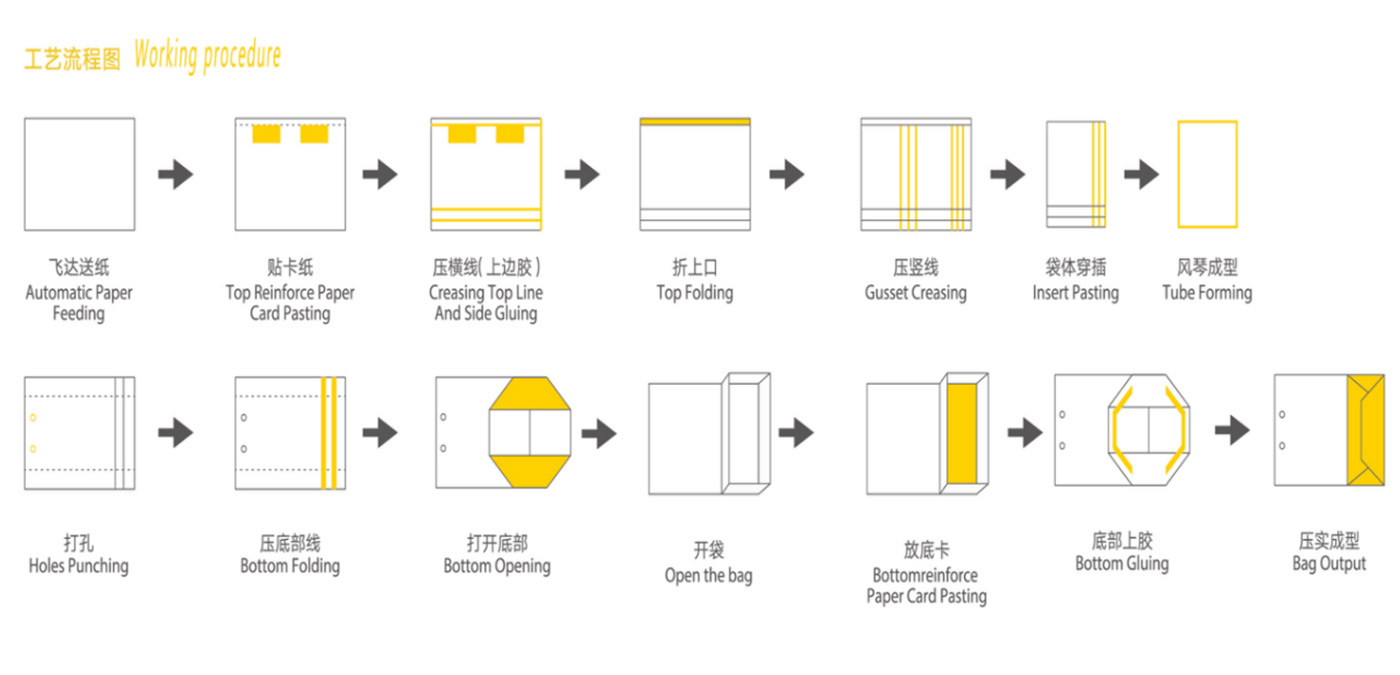

Working procedure

Working procedure

|

Model |

NEW HY-450TB-S |

|

Paper bag width |

110-450mm(4.33-17.72inch) |

|

Bottom width |

50-180mm(1.97-7.08inch) |

|

Paper sheet width |

340-1240mm(13.38-48.81inch) |

|

Paper sheet length |

210-600mm(8.26-23.62 inch) |

|

Paper weight |

a.Kraft paper:100-200g/m² b.Art paper+PP laminating:120-230g/m² c.White cardboard+PP laminating:150-250g/m² d.Grey Paperboard+PP laminating:150-300g/m² |

|

Recommend that paper thickness above 200gsm die cutting before operation |

|

|

Top card thickness |

200-450g/m² |

|

Top card width |

80-420mm /3.15*16.92inch |

|

Top card length |

20-50mm/0.78-1.96inch |

|

Max.bottom card |

100*440mm/3.93*17.32inch |

|

Min.bottom card |

50*190mm/1.96*7.48inch |

|

Bottom card thickness |

150-450g/m² |

|

Punching hole distance |

60、80、100、120、140mm |

|

Hole diameter |

Φ4,Φ5,Φ6 |

|

Working speed |

Punching hole distance can be customized according to actual needs,the above is the standard hole distance |

|

Glue type |

40-70pcs/min |

|

Total power |

water glue+hot melt glue |

|

Machine weight |

36KW 380V 50HZ |

|

Machine dimension |

18T |

High-speed feeder without stopping the machine, continuous paper feeding during operation, simple operation

The paper bag creasing line is a three-knife structure. When the paper is unfolded, the front knife pre-presses the horizontal line of the folding top of the paper bag, which is conducive to the perfect operation of the folding top. The rear knife pre-presses the two horizontal lines at the bottom of the paper bag, which is conducive to smoother bottom pulling of the paper bag after the tube is formed, and there is no creasing on the bag surface. Other brands of paper bag machines are all single-knife designs.

Folding lower suction device: The paper is fixed by the lower suction before the folding, and the paper will not be misplaced or shifted. The unique large roller climbing structure ensures that the paper runs smoothly after the folding action is completed. This function provides a perfect solution for the production of low-weight paper bags such as coated paper and kraft paper.

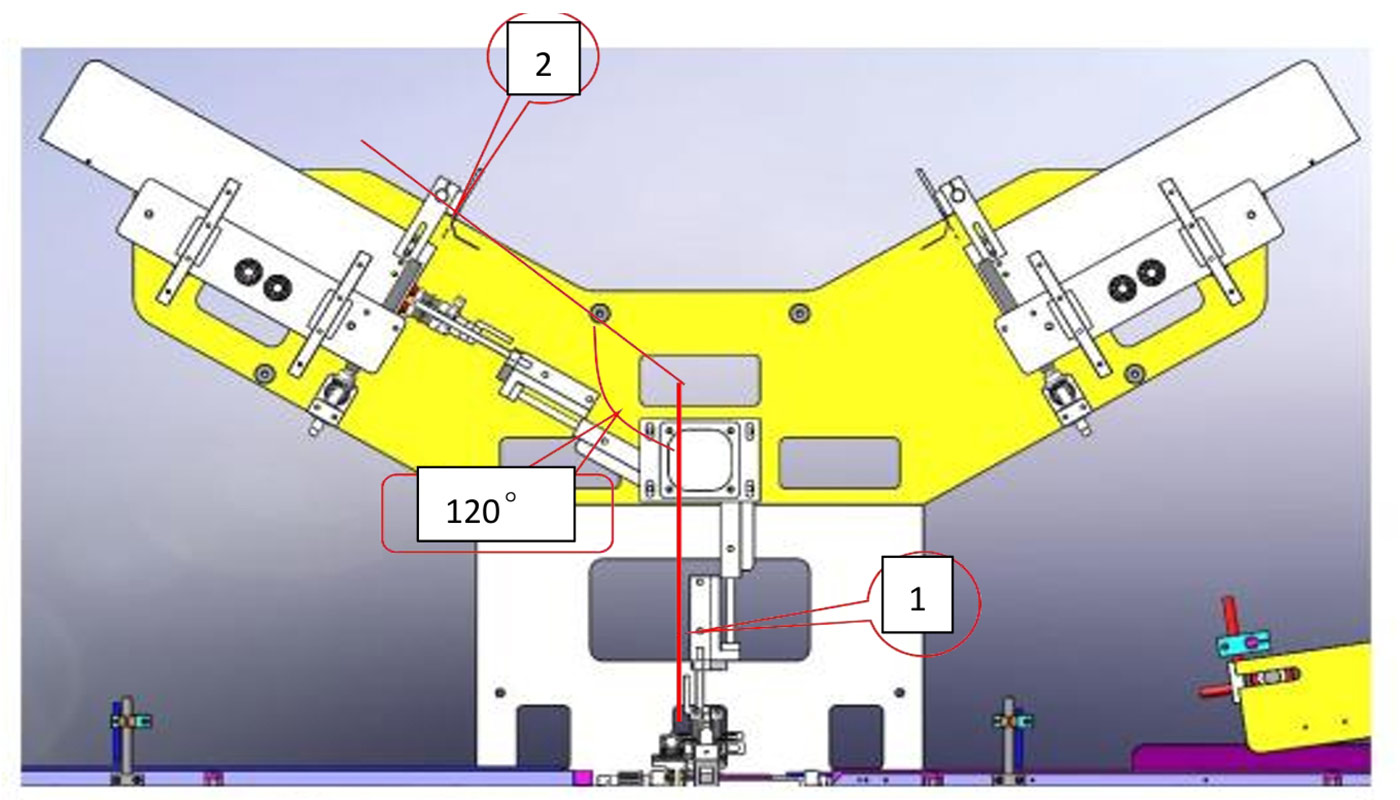

1, Glue position adjustment

2, Adjust the appropriate spray on the glue machine control panel according to actual use

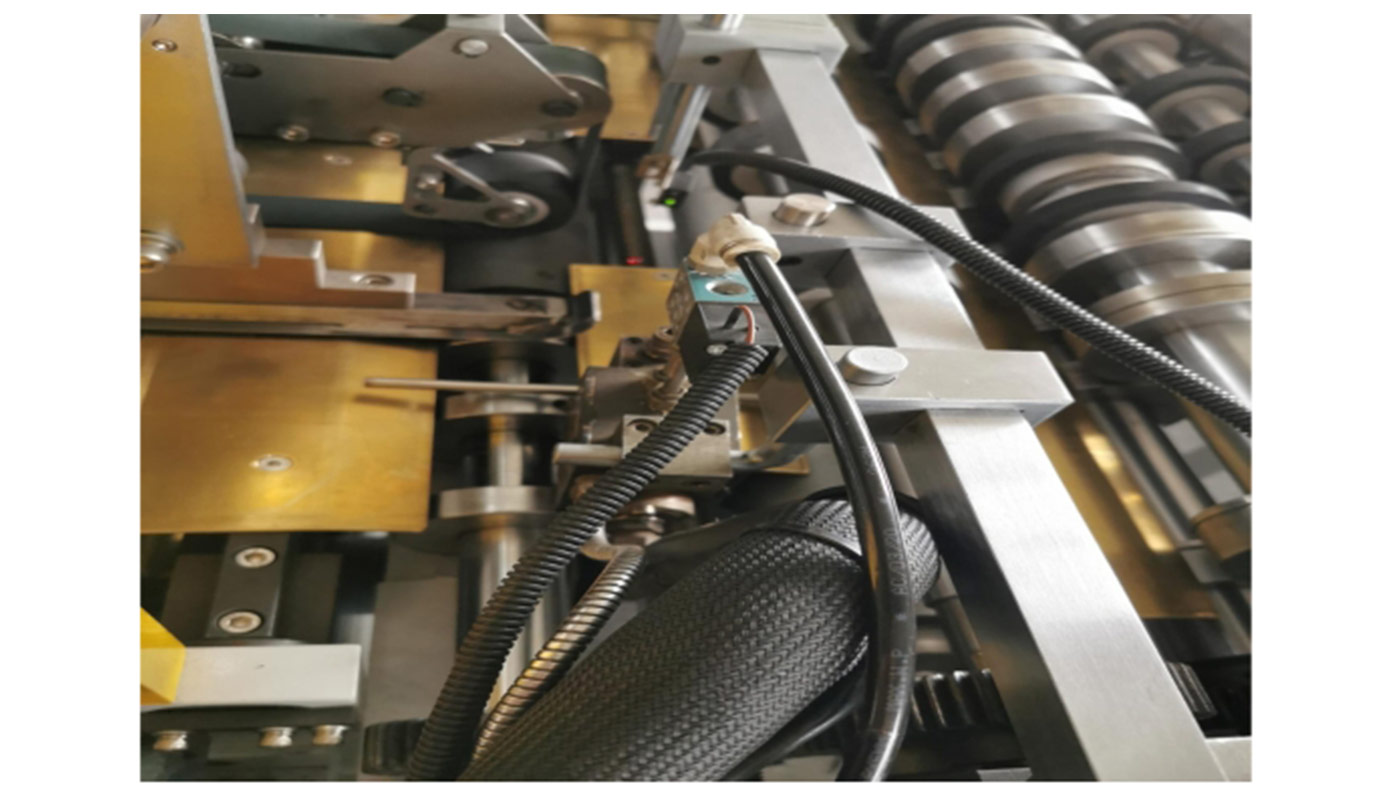

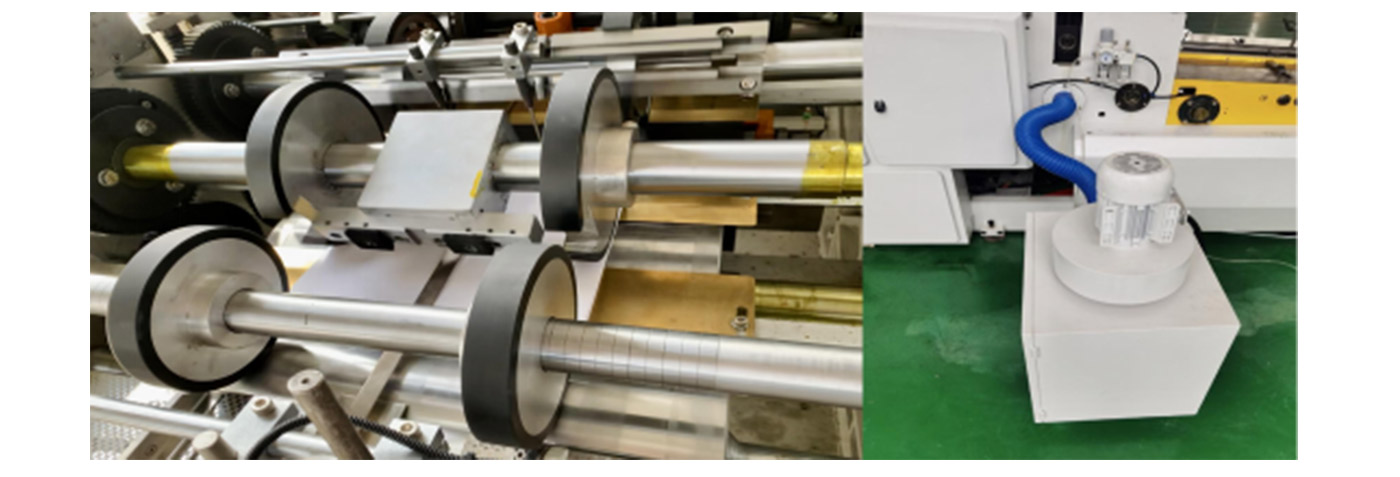

After the bags are rolled into tubes, they are transported by upper and lower rollers. The unique pressing wheel device can keep the paper tube flat during transportation, preventing the bags from automatically bulging due to the fluffiness of the paper itself after being rolled into tubes, thus affecting the operation.

Automatic punching device:

The hole spacing and hole diameter can be customized according to actual production needs. The punching mechanism is equipped with an automatic waste removal centrifugal pump device. During production operation, the paper foam after punching will be automatically removed and will not fall into the paper bag.

Pre-press the two horizontal lines at the bottom of the paper bag to create creases for the folded and opened bottom of the bag, making the bottom pulling action smoother. The strength of the indentation is related to the quality and thickness of the paper.

The sheet-type top card device can paste four or two top cards. It has a simple structure and is controlled by a separate servo motor. The lower card only needs to be rotated 120° to complete the card pasting action. It is easy to adjust.

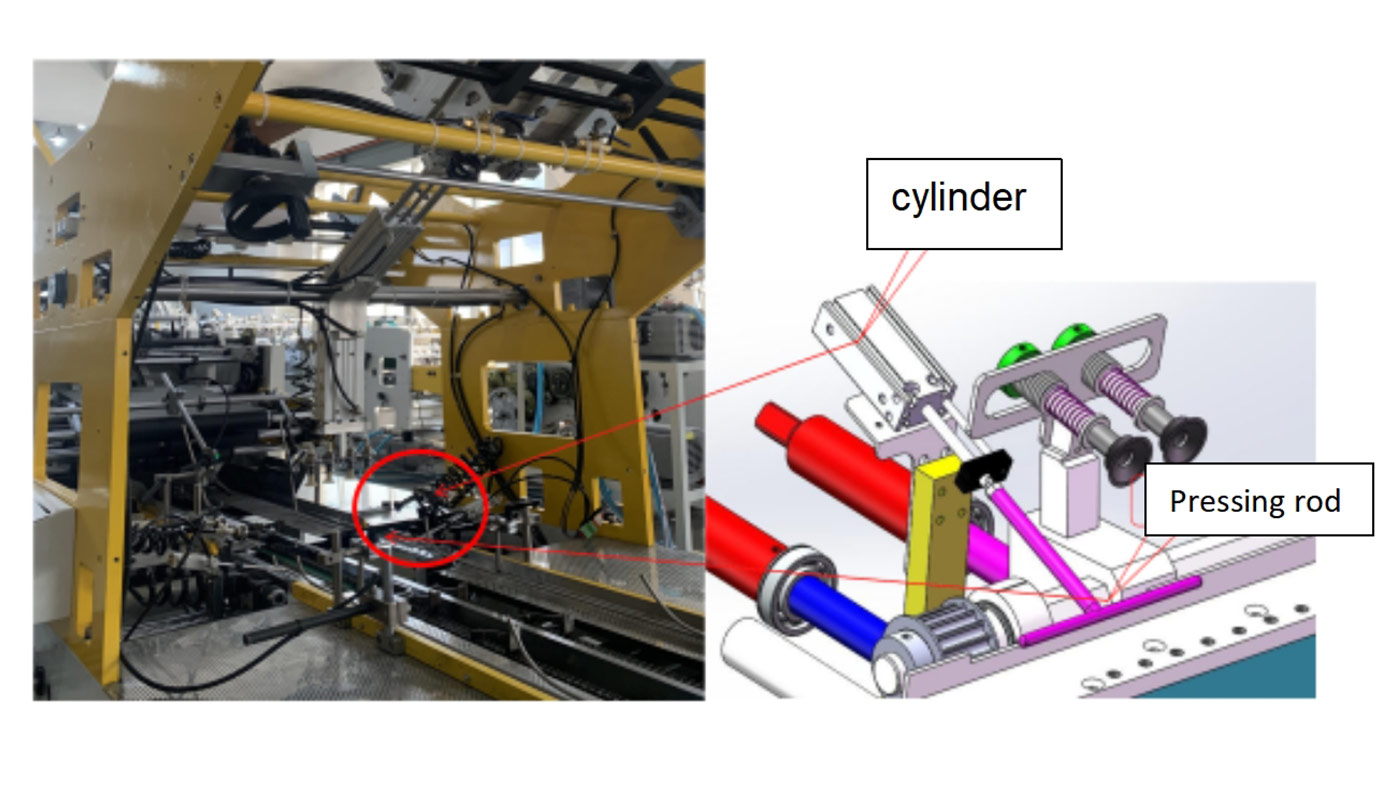

After the bottom card is placed at the bottom of the bag, the cylinders on both sides will perform a push-out action, and the paper pressing rod on the cylinder will quickly press down the upright bag bottom, so that the bottom card will not deviate when the conveyor chain starts quickly for conveying.

correct the gluing position of the bag bottom with the position of the gluing sponge blocks and fix them to achieve the bottom gluing action.

Patent unique bottom sealing design, the bottom pressed by the corrugated shaft, and the suspended blowing device blows the left side of the bottom to seal, which is then transmitted by the chain gear belt with the suction device. The rising mechanical arm closes the right side of the bottom, then compacted by the roller and formed by the pulley to complete the bag collection.

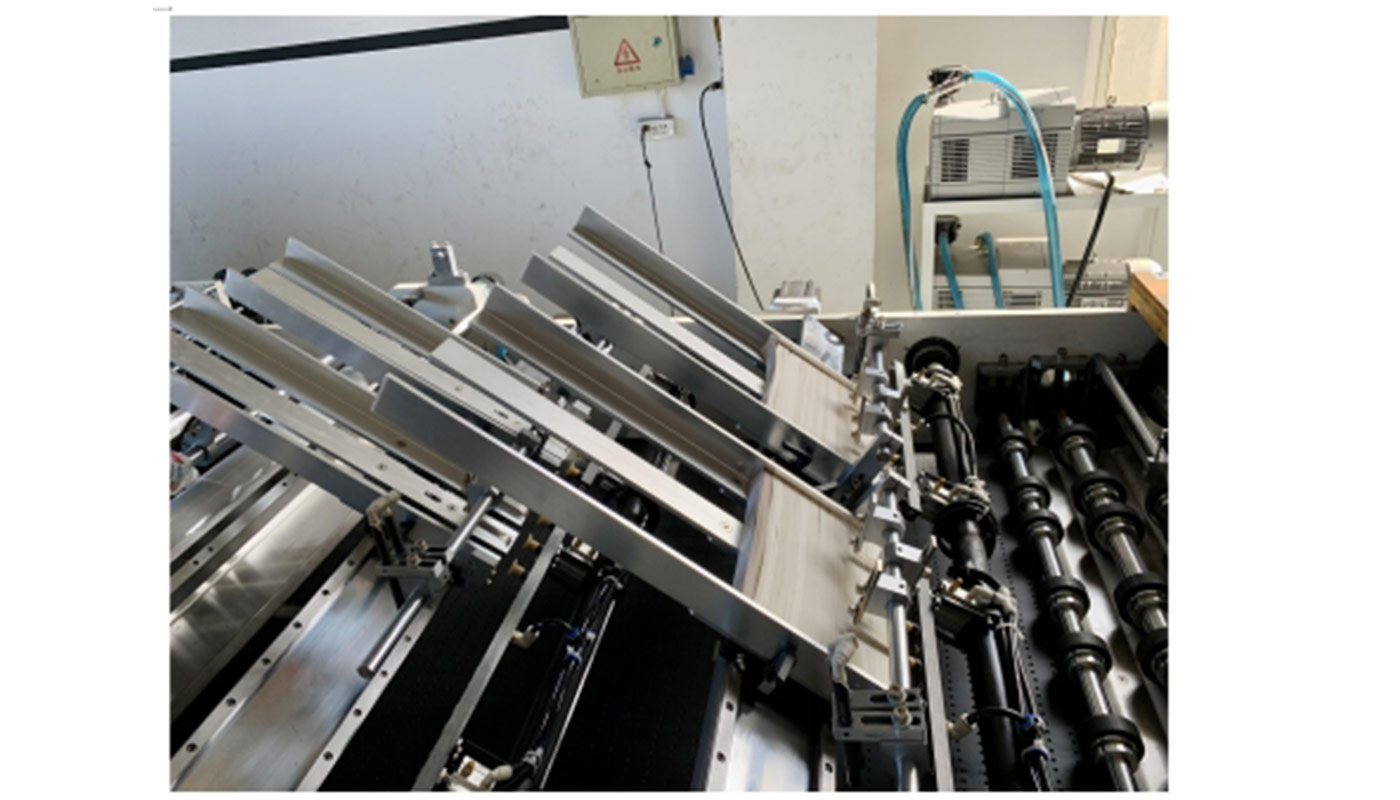

1, The bottom card picking and placing mechanism is driven by a separate servo motor to reciprocate. Double swing arms and double hoppers mode, the double swing arms are 120° apart, and the double hoppers are also 120° apart. When one swing arm ① places the bottom card, the other swing arm ② can simultaneously absorb the bottom card in the hopper, which can save the time of picking and placing. Compared with other similar models that need to rotate 180 degrees to absorb and place the card, at the same speed, the speed and output of our machine are increased by nearly 20%-30%.

2, Our structure is tilt design, the bottom card is not easy to drop down compared to other vertical structure.

The whole machine has a linear structure, occupies a small area, is flexible to install and place, and has more stable production and operation.

The creasing device is a three-blade structure, while similar products only have a single-blade design.

The top folding device is a downward suction and drum climbing structure.

The top card nozzle suction is controlled by a separate servo motor, which enables precise card placement, including color mark tracking and no card alarm.

Double-station bottom card pasting function, the bottom card is driven by a separate servo motor to rotate 120° for reciprocating motion. Compared with other similar models that need to rotate 180° to pick up and put cards, at the same speed, the speed and output of our model are increased by nearly 20%-30%

Bottom pressing conveying device, the bottom enter first and the cylinder pushes the paper pressing rod to quickly press the bottom of the bag down, and the bottom card will not deviate when the conveying chain starts conveying quickly

|

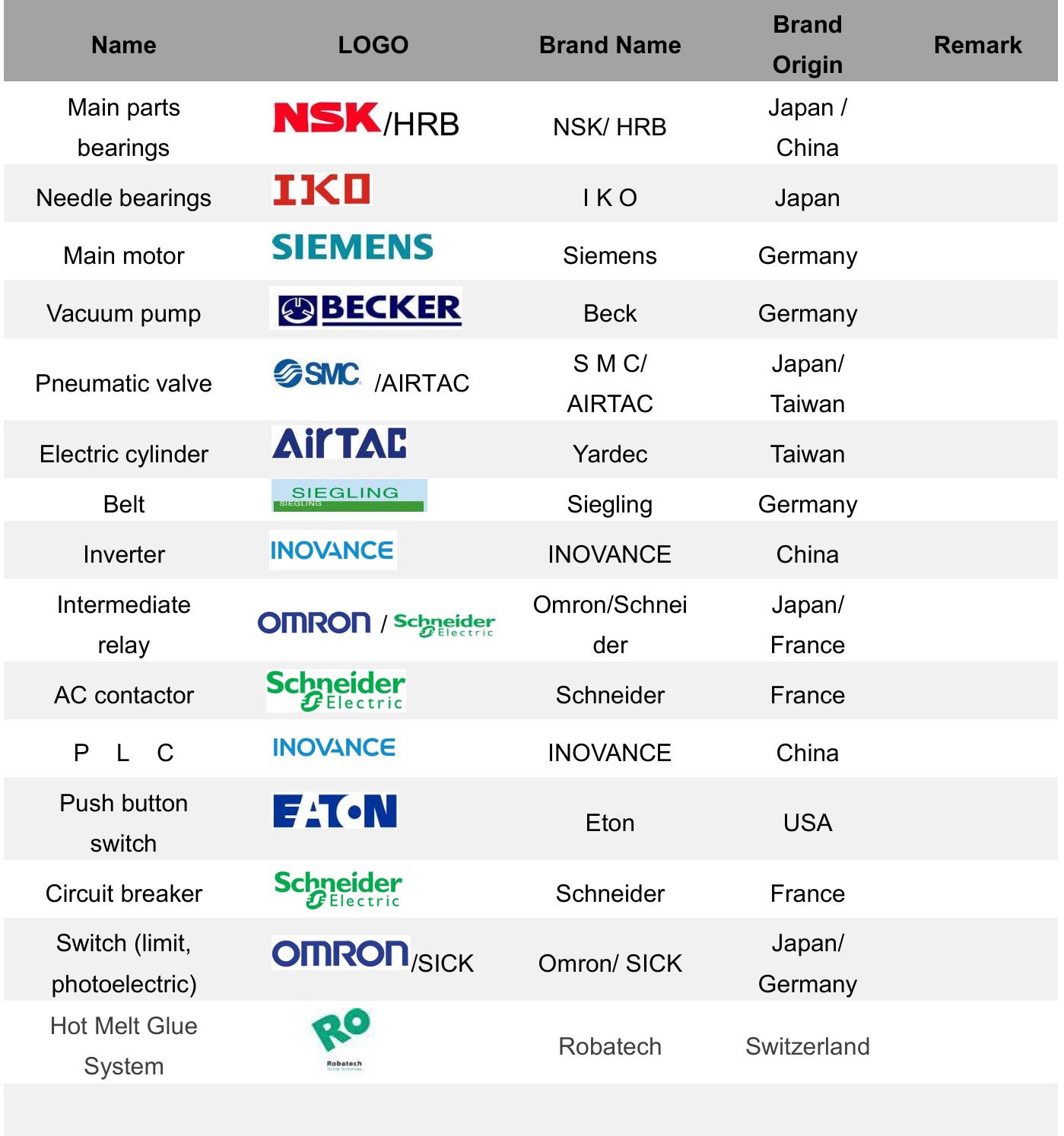

Main Configuration |

|

|

|

Mainmotor : Siemens Germany |

|

|

Vacuum pump: Becker Germany |

|

|

hot melt glue system: Robatech Switzerland |

|

|

Intermediate rely and Limit switch : Omron Japan AC contactor and Circuit breaker: Schneider France |

|

|

PLC:INOVANCE

|

|

|

Frequency converter:INOVANCE

|

|

|

Main bearing:NSK Japan

|

|

|

Main Belt: Siegling Germany

|

|

|

Main Belt: Siegling Germany

|

|

|

Photo electric: Omron Japan

|

Nov 15,2025

Nov 15,2025

Oct 11,2025

Oct 11,2025

Oct 11,2025

Oct 11,2025 GET A QUOTE