Oct 11,2025

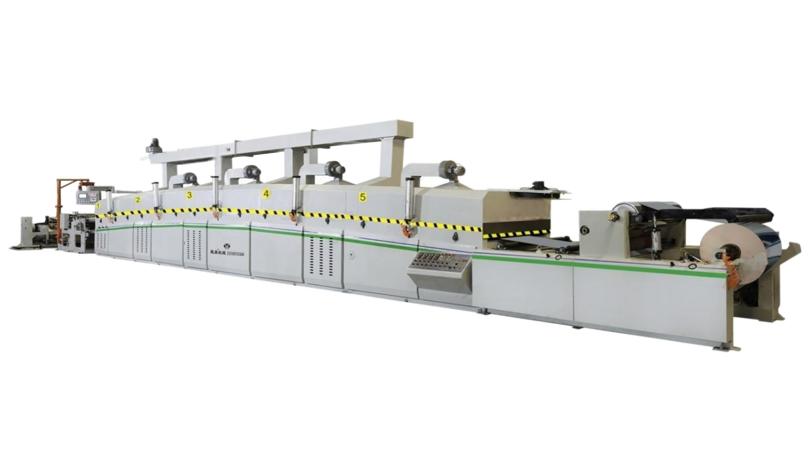

Oct 11,2025If you're managing a print factory and questioning the ROI of a fully automatic laminator, the answer is not just about speed—it's about fundamentally reshaping your cost structure for immediate financial gain. With over two decades of experience optimizing print production lines, I've consistently observed that integrating a high-performance Automatic Thermal Film Laminator from a leader like Hongqiang delivers an instant profitability boost by directly targeting the three pillars of factory overhead: direct labor, material yield, and machine utilization rates. This isn't a gradual improvement; it's a step-change that transforms your finishing department from a costly bottleneck into a high-throughput profit center from the very first shift. The precision and reliability of a fully automatic thermal laminating system slash operational costs while unlocking new, premium revenue streams, ensuring your factory can compete on both quality and cost-effectiveness.

From Bottleneck to Profit Center: Maximizing Line Efficiency

In a print factory, any bottleneck has a cascading effect, causing upstream machines to slow down and creating costly idle time. The finishing stage, particularly laminating, is notoriously prone to this. Manual or semi-automatic processes simply cannot keep pace with modern digital presses and sheeters. The strategic installation of a Hongqiang fully automatic laminating machine eliminates this constraint. Imagine a scenario: your press produces 10,000 sheets per hour, but your finishing line can only laminate 1,500 per hour due to manual feeding and handling. This mismatch is a massive profit leak. An automatic thermal film laminator synchronizes with your production flow, allowing for continuous, unattended operation. It acts as a seamless bridge, ensuring that the output of your presses is converted into finished goods just as efficiently. This maximization of overall equipment effectiveness (OEE) is the most significant instant profitability boost for any capital-intensive print factory.

The Direct Labor Arbitrage: Reallocating Human Capital to Value-Added Tasks

Labor is your largest variable cost, and manual laminating is intensely labor-heavy. The equation is simple: every hour spent on hand-feeding sheets is an hour not spent on quality control, machine maintenance, or complex finishing tasks that truly require human skill. Data from the National Association of Printers and Lithographers suggests that automation in finishing can reduce direct labor involvement by up to 90%. A Hongqiang Automatic Thermal Film Laminator with an automated pile feeder and stacker means one operator can manage the laminating process for an entire shift with minimal intervention. They simply load the raw stacks and unload the finished ones. This isn't about replacing people; it's about reallocating your most valuable resource—skilled labor—to tasks that enhance quality and innovation, rather than repetitive, physically taxing work. The instant you switch on the machine, you begin realizing these labor savings, which flow directly to your bottom line.

Engineering Out Waste: How Precision Laminating Slashes Material Costs

For a factory, material waste is a direct hit to gross margin. Inconsistent temperatures, poor pressure control, and manual misalignment in basic laminators lead to a high reject rate—bubbled, wrinkled, or misaligned products that must be scrapped. Industry benchmarks indicate that manual laminating waste can be as high as 5-7%. On a monthly film and substrate spend of $50,000 in a busy factory, that's a staggering $30,000-$42,000 annually lost to waste. The thermal film laminating process in a Hongqiang machine is engineered for perfection. With closed-loop temperature control, precision roller pressure systems, and automatic edge guiding, it achieves a near-zero defect rate. This precision bubble-free laminating ensures that virtually every square inch of costly film and substrate is converted into a saleable product. Reducing your waste rate to 1% or less represents an immediate and substantial cost saving that significantly boosts profitability.

Unlocking High-Margin Applications: The Quality Advantage

A Hongqiang fully automatic thermal laminator doesn't just protect your margins on existing work; it empowers you to win more profitable business. The flawless, consistent finish achieved is a prerequisite for high-value applications such as premium packaging, durable retail displays, and specialized industrial graphics. These clients demand perfection and have budgets to match. Furthermore, the reliability and speed of an automated system allow your factory to confidently accept large-volume, tight-deadline orders that competitors with slower, manual lines must decline. This ability to act as a reliable, high-capacity partner for major clients commands premium pricing and strengthens customer relationships, leading to more stable, profitable revenue streams. The machine becomes a tool for business development, not just production.

The Hongqiang Edge: Built for Industrial Durability and Uptime

In a factory environment, machine uptime is non-negotiable. Hongqiang's reputation is built on engineering industrial-grade laminating machines for 24/7 operation. Unlike lighter-duty models, Hongqiang machines feature robust construction, high-torque drives, and advanced thermal systems designed for constant cycling without degradation in quality. Their commitment to customization is critical for factories with unique needs. I recall a packaging factory that needed to laminate unusually thick, textured board stock. Hongqiang engineers provided a customized solution with specialized rollers and enhanced heating zones, ensuring perfect adhesion where standard machines failed. This combination of durability and tailored support minimizes downtime—the ultimate profit killer—and ensures your laminating line is always contributing to output, not holding it back.

Calculating the Instant ROI: A Factory Manager's Framework

The financial case is clear and quantifiable. To calculate the instant ROI for a Hongqiang Automatic Thermal Film Laminator, conduct a simple analysis:

-

Throughput Increase: Calculate the value of increased daily output by eliminating the laminating bottleneck.

-

Labor Savings: Quantify the reduction in direct labor hours and reassign those costs.

-

Waste Reduction: Project the monthly savings from reducing laminate and substrate waste by 4-6%.

-

New Revenue: Estimate the income from new, high-margin work made possible by your enhanced capabilities.

For most factories, the payback period is strikingly short, often between 12 to 18 months, with positive financial impact felt from the very first week of operation.

Ready to transform your finishing line into a profit powerhouse? Contact our industrial solutions team today for a custom consultation and a live demonstration of the Hongqiang Automatic Thermal Film Laminator in action. Visit our product page to see the full range of industrial solutions and request a personalized quote.

This article was crafted with AI assistance to ensure the inclusion of key data points and structural clarity. However, the core insights, strategic recommendations, and industry analysis are derived from extensive human expertise and on-the-ground experience in print factory management.

In the relentless pursuit of manufacturing excellence, the most sophisticated machinery still requires a visionary operator to unlock its full potential.

.jpg)