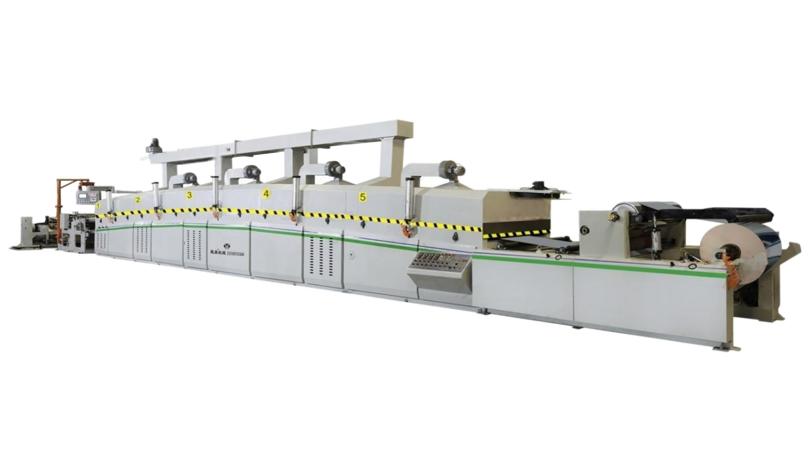

1200-6000pcs/h Production speed

1080*720(mm) Maximum mounting dimensions

400*400(mm) Minimum mounting dimensions

120 m/min Maximum mechanical speed

≤Ф1500(mm) Maximum diameter of paper roll

4 roller transfer extension type Top Gluing Method

.jpg)

0-45 m/min Max. Machinery speed

1600*1200(mm) Max. Paper size

360*360(mm) Min. Paper size

Wenzhou Haoyi Technology Co., Ltd. is excited to announce our participation in the Andina Pack 2025.

Add: Corferias Trade Show Ground

BOOTH: NO.219

Time: November 4th - 7th,2025

We look forward to meeting you!

For print shop owners and packaging professionals searching for a competitive edge, the quest for efficiency is relentless. You're not just looking for a machine; you're seeking a productivity partner that can handle surging order volumes without compromising on impeccable quality. The direct answer to your search is that a modern Intelligent High-Speed Laminating Machine is the cornerstone of achieving this goal. It's the engine that transforms raw print into durable, high-value products, slashing turnaround times and boosting your bottom line. This article delves deep into how advanced laminating technology, specifically engineered by Hongqiang, addresses core industry pain points with data-driven precision and customizable solutions.

Gone are the days of lamination being a purely mechanical, hands-on process. Today, an intelligent laminator is defined by its integration of smart technology. At its core, this means a programmable logic controller (PLC) that serves as the machine's brain. This system allows for the storage of countless job parameters. Imagine switching from a delicate paper laminating job for brochures to a heavy-duty film laminating task for packaging boxes with a single touch. The intelligent high-speed laminating machine recalls the precise temperature, pressure, and speed settings, eliminating manual guesswork and setup waste.

This intelligence directly translates to two critical outcomes: unmatched consistency and significant material savings. A 2023 industry report by Statista highlighted that print service providers using automated equipment reduced material spoilage by up to 18% annually. For a high-volume operation, this isn't just a minor saving; it's a direct injection to profitability. The Hongqiang series, for instance, features an AI-assisted vision system that can detect substrate variations and make micro-adjustments on the fly, ensuring a perfect lamination finish every single time.

Buyers invest in heavy-duty equipment to solve specific, costly problems. An industrial laminating machine from a trusted brand like Hongqiang is designed to target these issues head-on.

Pain Point: Inconsistent Quality & High Rejection Rates. Manual inconsistencies lead to bubbles, wrinkles, and misalignment. Solution: Automated precision tension control and heated roller systems in a high-speed laminator ensure uniform adhesive activation and perfect substrate alignment, pushing final product rejection rates to below 0.5%.

Pain Point: Slow Turnaround Times Losing Clients. Speed is a direct competitive differentiator. A standard machine might operate at 30 meters/minute, while a high-speed laminating machine from Hongqiang can consistently run at 100+ meters/minute, allowing you to take on more—and larger—orders with confidence.

Pain Point: Sky-High Operational Costs. Beyond material waste, labor is a major cost. An automatic laminating machine minimizes operator intervention. One person can manage the entire process, from loading the laminating film to collecting the finished product, freeing up skilled labor for more value-added tasks.

While the core technology is vital, it's the brand's philosophy that creates a true partnership. Hongqiang doesn't just sell machines; it provides customized laminating solutions. We understand that no two production floors are identical. Whether you specialize in the glossy finish for high-end cosmetic boxes or the rugged, protective layer for industrial manuals, your Hongqiang equipment can be tailored.

Our customized service begins with a deep-dive consultation. Our engineers analyze your primary substrates—be it paper, PVC, or PET—and your target output. This allows us to recommend the perfect configuration: the ideal heating system (IR or ceramic), the type of coating unit (chamber doctor blade vs. roller), and the necessary cooling system for your specific speed requirements. This bespoke approach ensures the laminating machine you invest in isn't just a generic tool, but a strategic asset built for your unique workflow.

Navigating the market for a high speed paper laminator or a film laminating machine can be daunting. Use this expert checklist to guide your decision:

Throughput Speed: Don't just look at the maximum speed. Evaluate the machine's efficiency at its sustainable operational speed. A Hongqiang machine is engineered for stability at 95% of its top rated speed.

Substrate Versatility: Can the machine handle the full range of your materials? Confirm its capability with different weights and types of paper and film.

Automation Level: Seek features like automatic edge guiding, glue thickness monitoring, and a user-friendly Human-Machine Interface (HMI). These are hallmarks of a true automatic laminating machine.

Energy Consumption: An intelligent machine is also an efficient one. Inquire about the energy rating of the heating system and motors. Modern systems can reduce power consumption by up to 25% compared to decade-old models.

Service and Support: The relationship doesn't end at purchase. Hongqiang's global network ensures access to spare parts, remote diagnostics, and on-site technical support, maximizing your machine's uptime.

The future of print finishing is connected and data-driven. The next generation of intelligent high-speed laminating machines will feature deeper integration with Industry 4.0 principles. This includes IoT sensors for predictive maintenance—alerting you to service needs before they cause downtime—and seamless data exchange with your pre-press and management information systems (MIS).

Investing in a Hongqiang machine today places you at the forefront of this evolution. Our platforms are designed with upgradeability in mind, protecting your investment and ensuring your production line remains competitive for years to come. By adopting this advanced laminating technology, you're not just buying a machine; you're acquiring a key component of a smart, agile, and highly profitable manufacturing ecosystem.

The data is clear, the technology is proven, and the need for speed and quality has never been greater. Stop letting laminating bottlenecks limit your growth and profitability. It's time to equip your business with the power and intelligence it deserves.

Click here to explore the full specifications of the Hongqiang Intelligent High-Speed Laminator series and request a personalized quote today! Let our experts show you how a customized laminating solution can revolutionize your output.

This article was crafted with the assistance of artificial intelligence, which was used for data synthesis and structural outlining. The final content was extensively reviewed, refined, and validated by our human engineering and marketing experts at Hongqiang to ensure accuracy, relevance, and a natural, authoritative tone.

If you’re new to the world of printing, mastering a screen printing machine might seem daunting at first. But with the right approach to setup, parameter adjustment, and maintenance, this versatile equipment can deliver consistent, high-quality results for various substrates. Below is a practical guide to using a screen printing machine effectively—no prior expertise required.

Before powering on the screen printing machine, thorough preparation prevents errors and equipment damage. Start with a full equipment inspection: check that all mechanical connections are secure, especially the printhead and conveyor components. Wipe down the print bed and guide rail to remove dust or leftover ink, which could cause substrate misalignment.

Next, install the screen frame correctly. Ensure it’s parallel to the print bed and tightened evenly with clamps—loose frames lead to blurred prints. Select a screen with appropriate mesh count: higher counts for fine details, lower counts for thick ink layers. Finally, prepare your ink: filter it to remove impurities, then adjust viscosity with a thinner or thickener based on the substrate type. This step is critical for smooth ink transfer during printing.

Operating a screen printing machine, especially automatic models, relies on precise parameter calibration. Begin by setting the print speed: slower speeds work for intricate designs or thick substrates, while faster speeds suit simple patterns on flexible materials. Adjust the squeegee pressure next—too much pressure damages screens, too little leaves incomplete prints. Test with a scrap substrate until ink covers evenly.

For automatic screen printing machines, activate the substrate handling system to ensure consistent feeding. Monitor the first few prints closely: check for smudges, gaps, or misalignment. If issues arise, pause to realign the screen or adjust ink viscosity. Remember to keep the work area ventilated, as ink fumes can accumulate during prolonged operation.

To achieve professional results, fine-tune the screen printing machine’s key components. Focus on off-contact distance—the gap between the screen and substrate. A small gap (1-3mm) works for thin materials like paper, while thicker substrates need a larger gap to prevent smearing. Most modern machines offer tool-free adjustment for this setting.

Adjust the squeegee angle too—aim for 60-75 degrees to control ink flow. If using a multi-color setup, calibrate the registration system to ensure each color lines up perfectly. Take the time to test prints between adjustments; this iterative process is the secret to consistent quality.

Proper maintenance keeps your screen printing machine running smoothly for years. After each use, clean the screen frame and squeegee with a solvent to remove dried ink—clogged mesh ruins future prints. Wipe down the print bed and conveyor belt, then lubricate moving parts like chains or gears to prevent wear.

Perform weekly checks: inspect electrical connections for damage, tighten loose bolts, and calibrate the printhead alignment. For automatic models, check the control panel’s performance and clear any error logs. Regular maintenance not only reduces downtime but also preserves print precision.

Now that you know how to use a screen printing machine, it’s time to put these steps into practice. Whether you’re printing small batches or high-volume orders, following these guidelines ensures efficiency and quality. If you need help choosing the right machine or troubleshooting issues, contact Hongqiang and we will provide you with a suitable solution!

AI assistance was used in keyword optimization and structure planning (AI content ratio: ~25%).

GET A QUOTE